We Here To Help !

Our Suggestion On Common Maintenance Issues

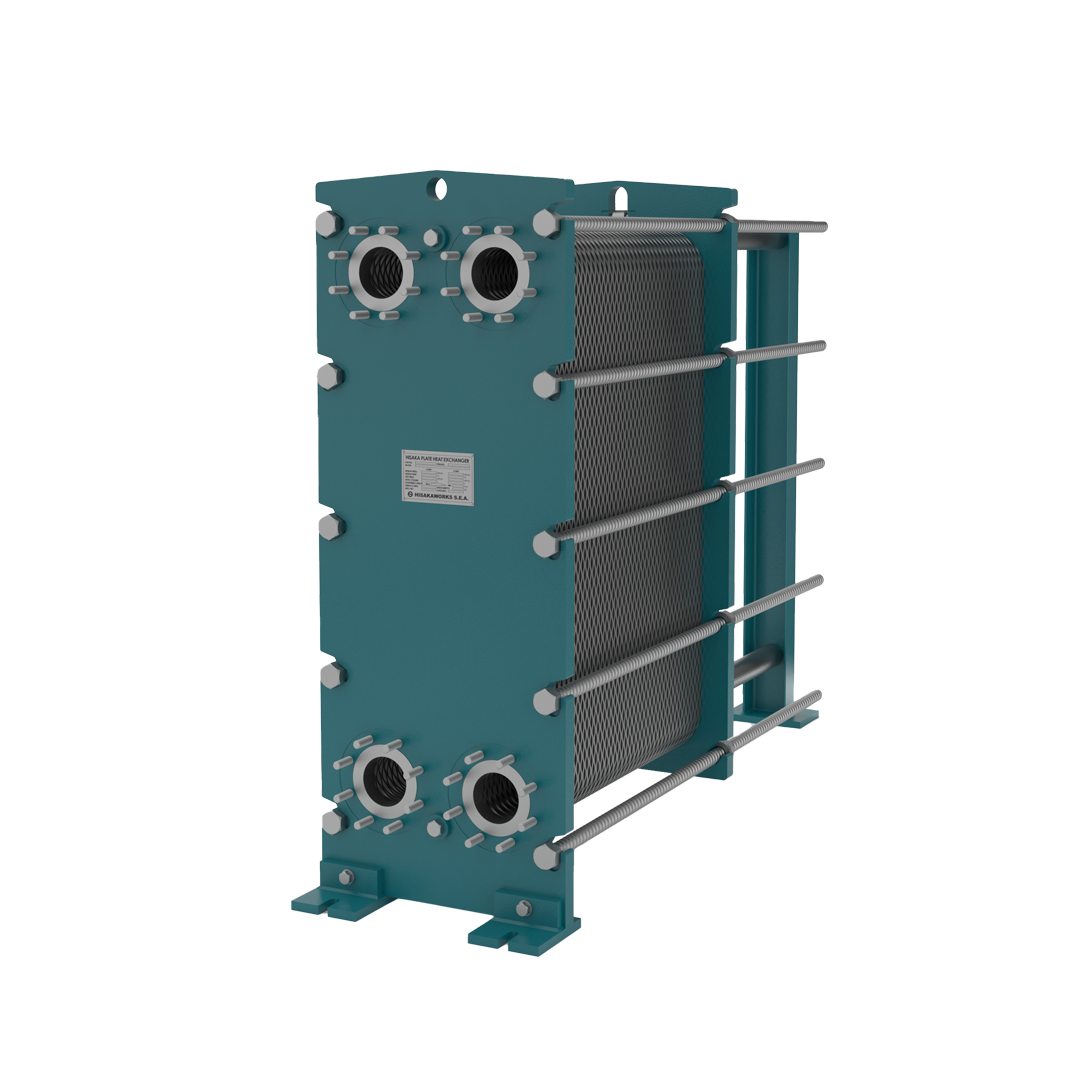

Issue 1: Phosphate sludge build up on plate surface

This issue may occur due to the solidification of phosphate solution on the heat exchanger plate surface. When the plate heat exchanger has stopped operation for a while, the residue of phosphate solution on the plate will solidify which blocks the corrugation of the plate and reduce the heat transfer efficiency.

HISAKA suggestions:

- Number of plates used must be the same as per the specification provided, any under spec will cause quicker choke up.

- Use model EX-15 Heat Exchanger (washboard pattern) to reduce contact points.

- Consult professional to perform chemical cleaning immediately.

- Plan preventive maintenance.

Issue 2: Total corrosion on plate surface

This issue may occur due to the plate heat exchanger is being operated with highly corrosive liquid that contained fluoride. When plate heat exchanger operates with highly corrosive liquid, it can corrode in between the seal line and the plate which caused penetration crack, and intermixing of two liquids will occur.

HISAKA suggestions:

- Up to date, there is no plate material that is completely resistant to fluoride, proper preventive maintenance is very important to mitigate this issue.

- Prepare an additional set of plate packs in case of leakage occurs.

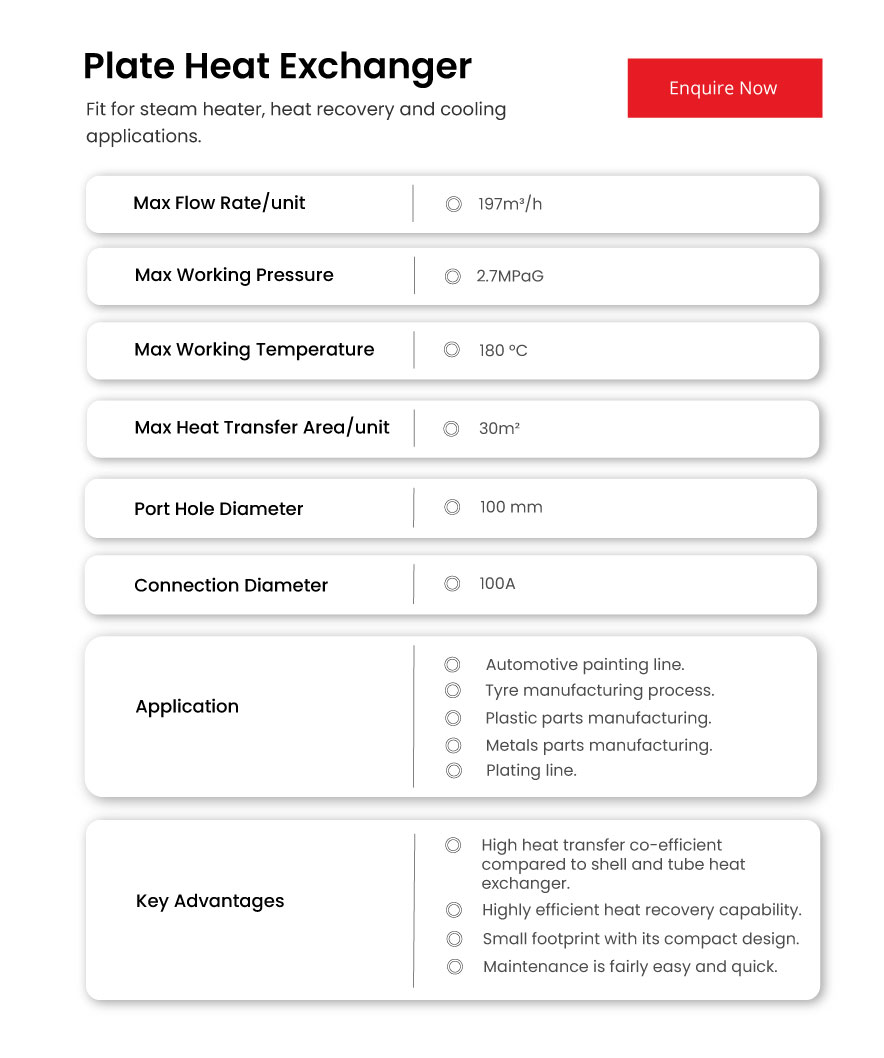

RX-10

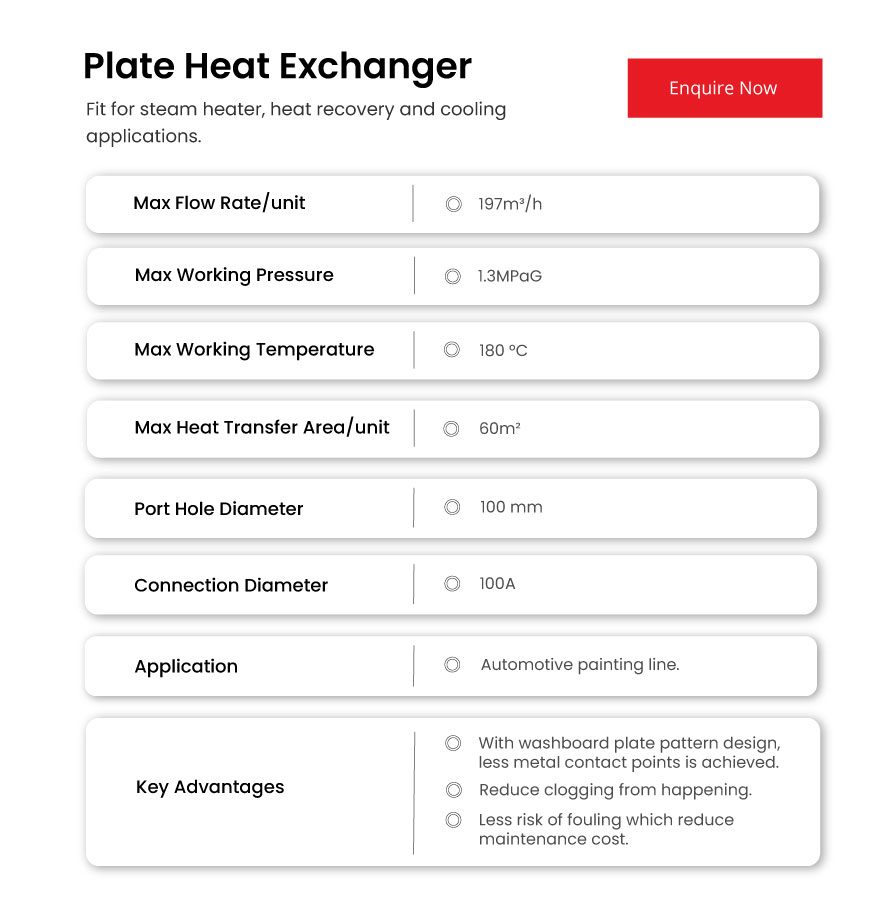

RX-10 EX-15

EX-15

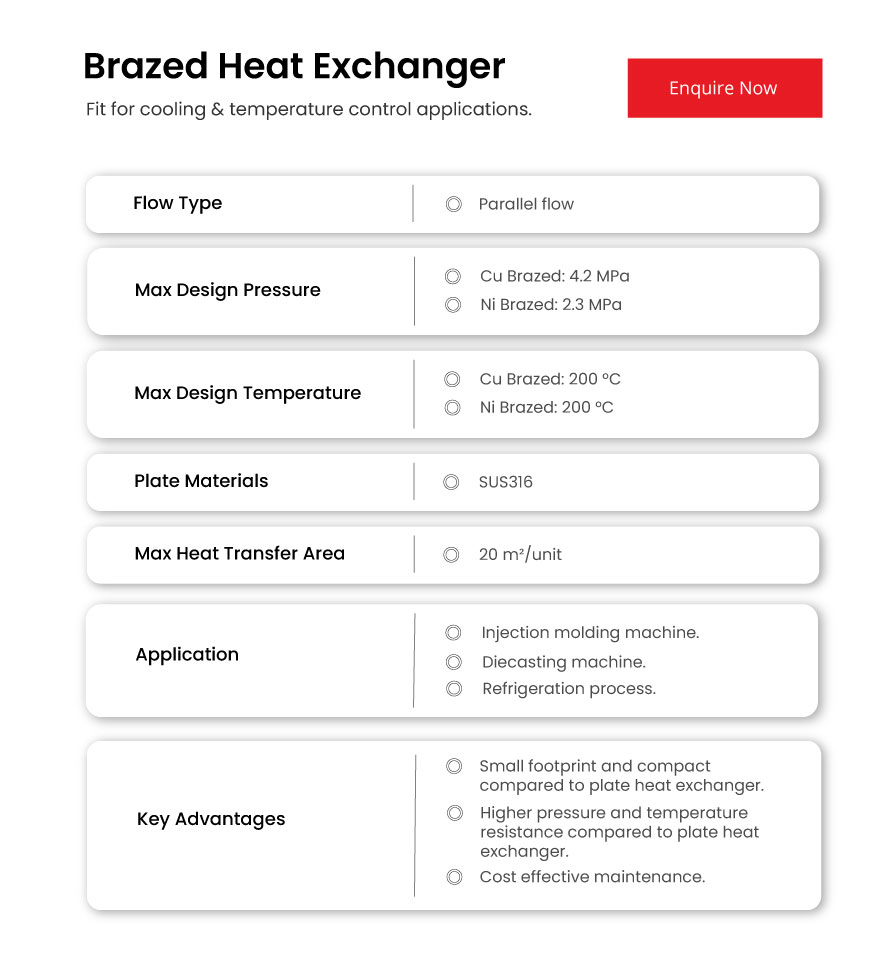

BX-50

BX-50

HF5 (CA)

HF5 (CA) TB5

TB5 HJ5-TDT, TST

HJ5-TDT, TST