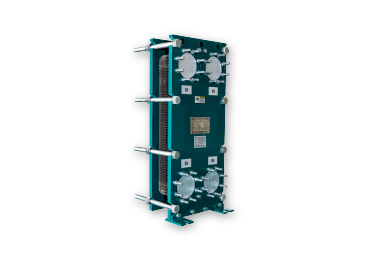

The plate heat exchanger is a type of heat exchanger that can be installed in the process line or utility line to heat or cool a fluid. It uses a very thin sheet of corrosion-resistant metal (such as stainless steel, or titanium) to transfer heat between two fluids. Compared to a conventional heat exchanger, a plate heat exchanger has a larger surface area, thus the heat transfer rate is increased.

The plate heat exchanger is used to transfer thermal energy between two fluids without allowing the fluids to mix together. Multiple plates are stacked together and gaskets installed on the plate to prevent the fluids from entering alternating plates. Thus, fluids flow into the channel counter-currently in the heat exchanger to achieve optimal heat transfer.

Semi welded plate heat exchangers are commonly used in Sulfuric Acid, BTX Recovering processes, and many other industrial processes. HISAKA WX series is made to perform in rough condition due to a special welded design.

HISAKA GX series Plate Heat Exchangers are suitable for slurry, sludge and crystal-containing fluid. HISAKA GX series PHE is commonly used in Waste Water, Plating, Food Processing, and Pulp and Paper industry.

HISAKA dual wall Plate Heat Exchanger are made to avoid intermixing of two fluids when one heat transfer plate is damaged. With HISAKA dual wall PHE, leaked fluid will be discharged to prevent intermixing.

HISAKA YX series Plate Heat Exchanger is innovatively designed to improve the efficiency of your condenser. Our YX series Plate Heat Exchangers are widely used in beer processing plants, bioethanol plants, and sugar refineries. With its special YX plate pattern, YX series is compact, light, and can be easily installed.

Eager to know more about HISAKA plate heat exchanger? Fill up the form below and our dedicated specialist will contact you as soon as possible. Or do you have specific requirements for your PHE? Provide us the specification you need and our specialist can suggest the most suitable model for you. If urgent, you can always contact our nearest agents or sales representative.