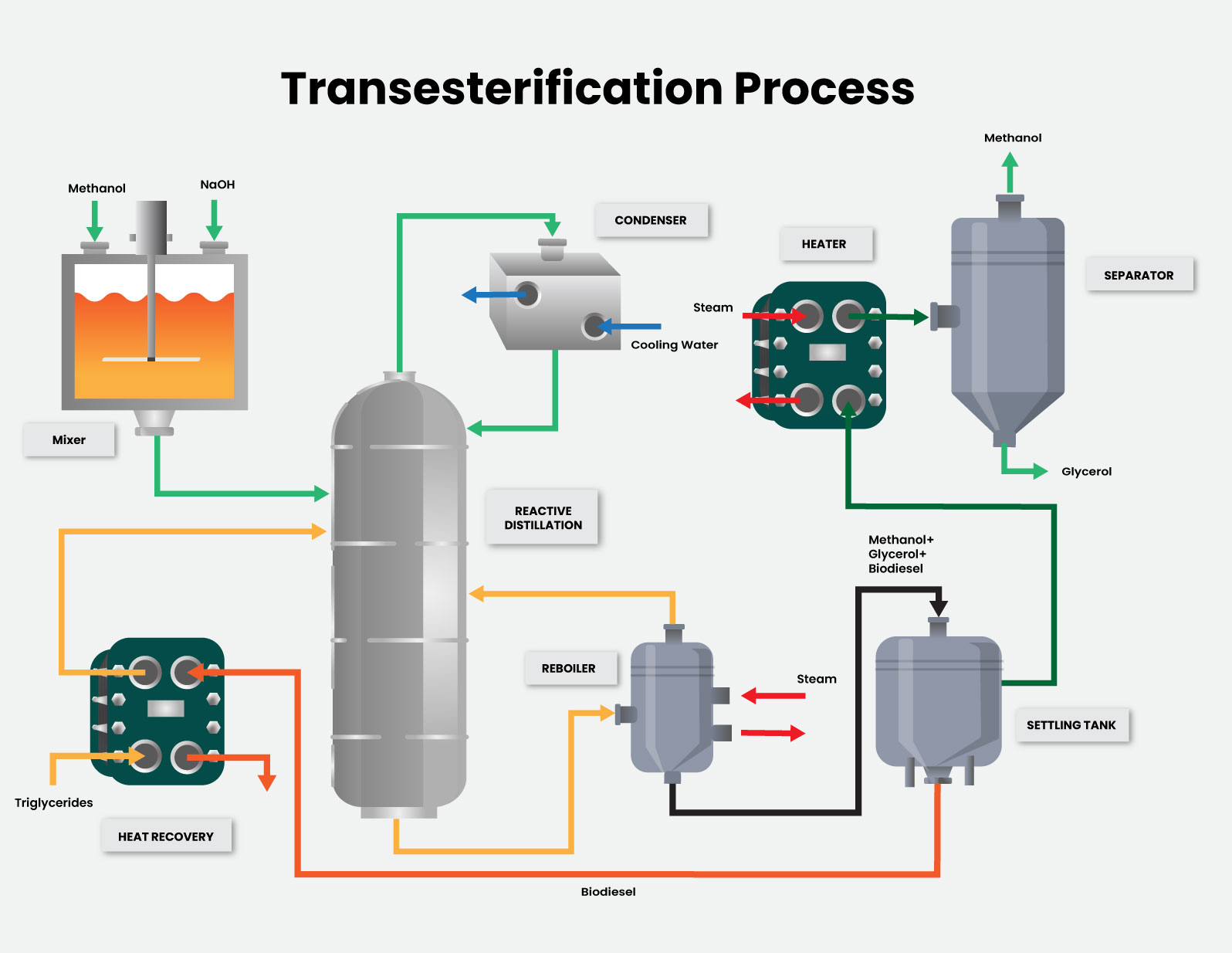

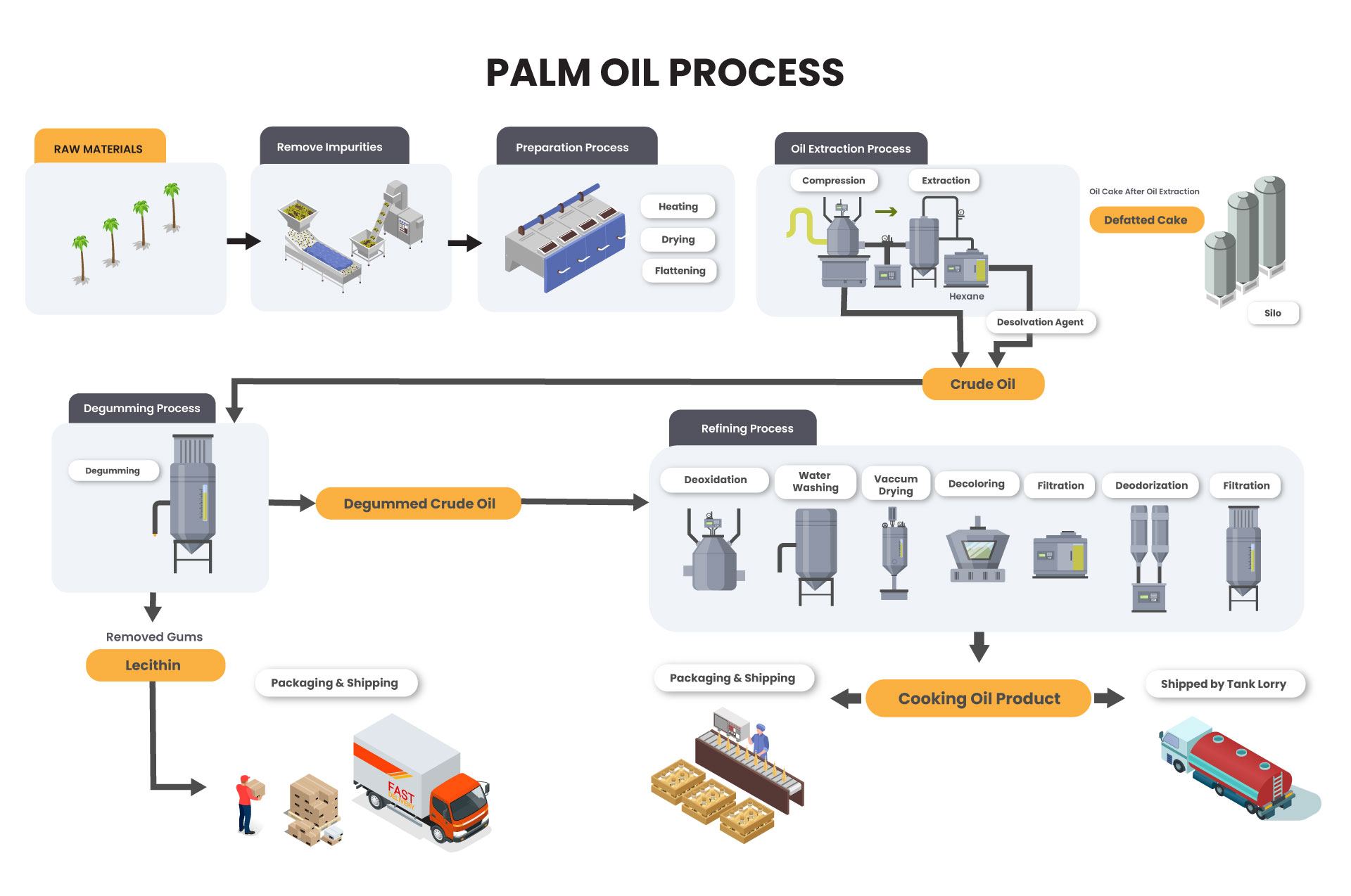

Process Flow Diagram

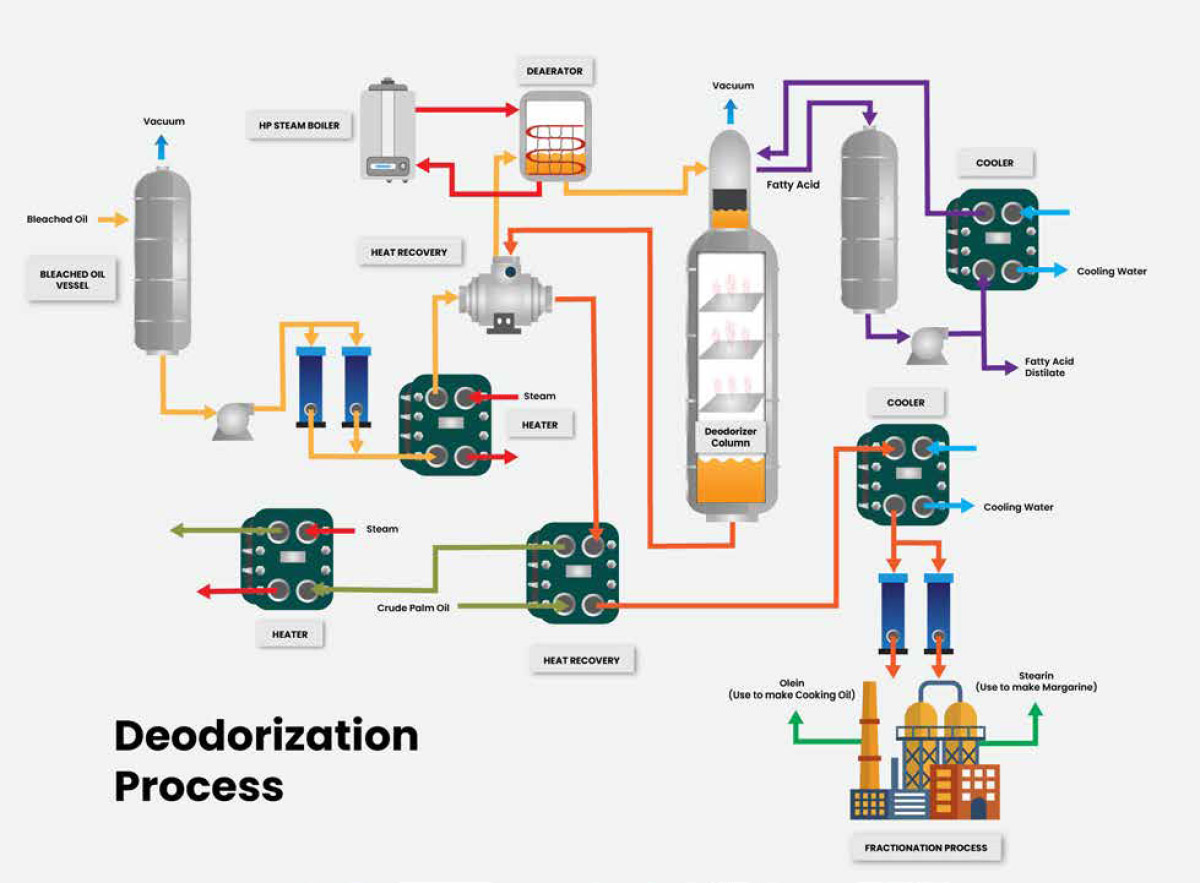

Deodorization Process

Deodorization process of palm oil is the final process to process crude palm oil into edible palm oil, which in the deodorization process, it involves many different processing stages.

Crude palm oil transported to a palm oil refinery stored in a storage tank will first undergo purification process.

First, the degumming process is used to separate the gums by adding phosphoric acid to heated crude palm oil (the gums are the impurities that will be removed in the bleaching stage). Next, the treated palm oil will be undergoing bleaching process where bleaching earth (activated clay) is used to absorb all the color pigments contains in the treated palm oil.

After the bleaching process, the bleached palm oil will be sent to the filtration process to remove all the bleaching earth. Lastly, the bleached palm oil will be undergoing deodorization process to remove the odor where the palm oil is heated and the vapor (palm fatty acid distillate (PFAD)), is removed from the oil.

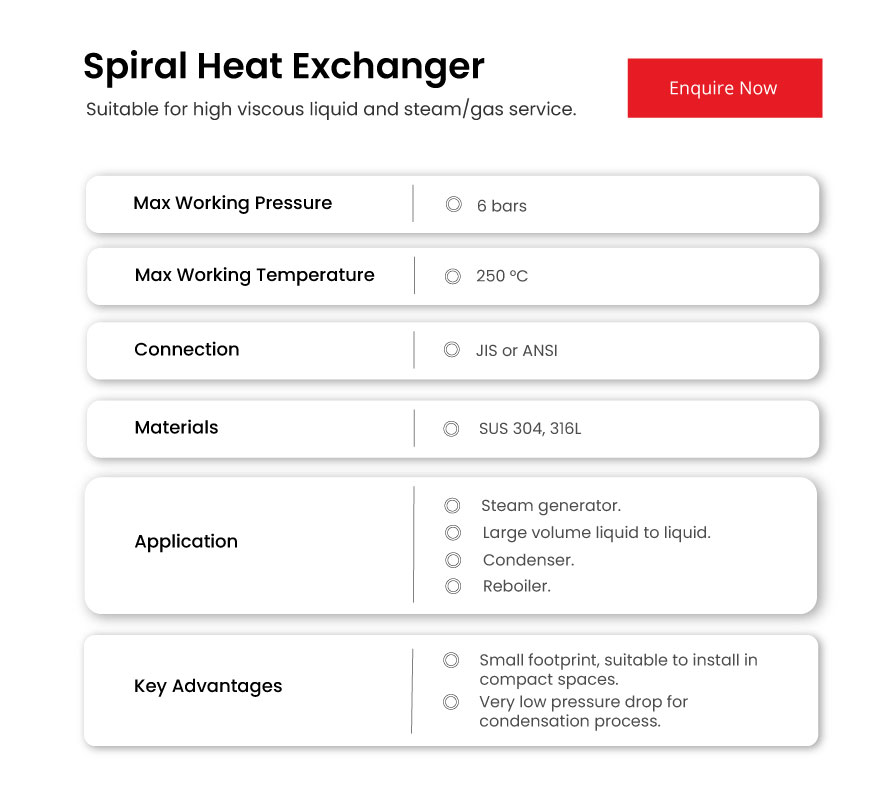

Where can we apply an economizer for heat recovery in the deodorization process?

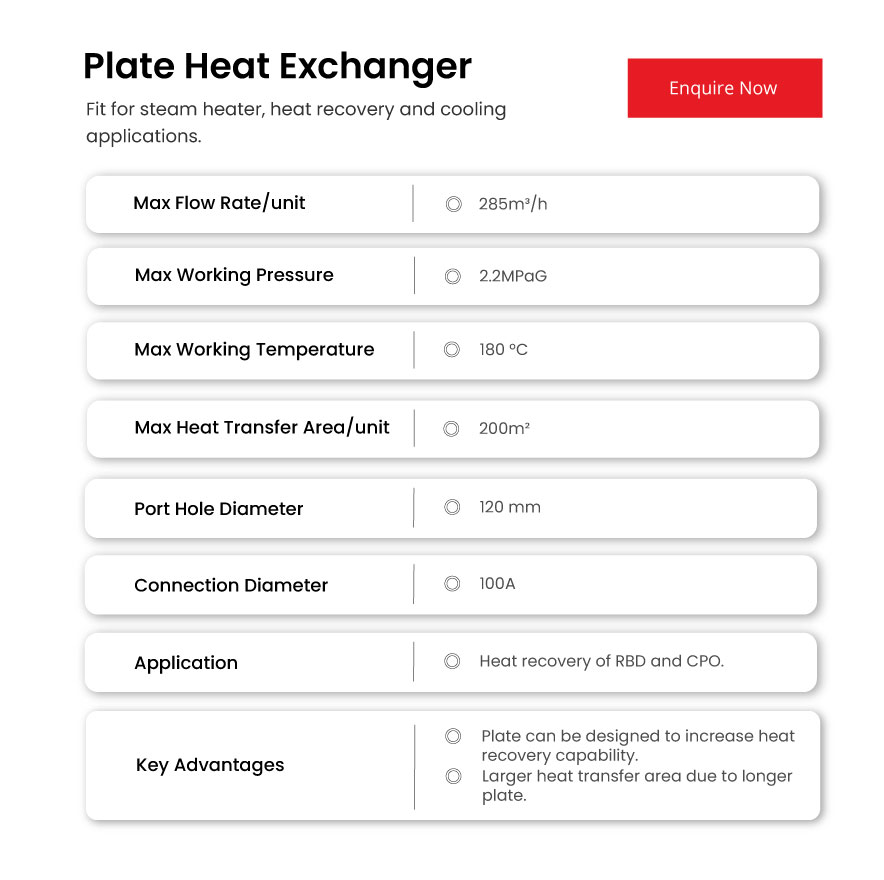

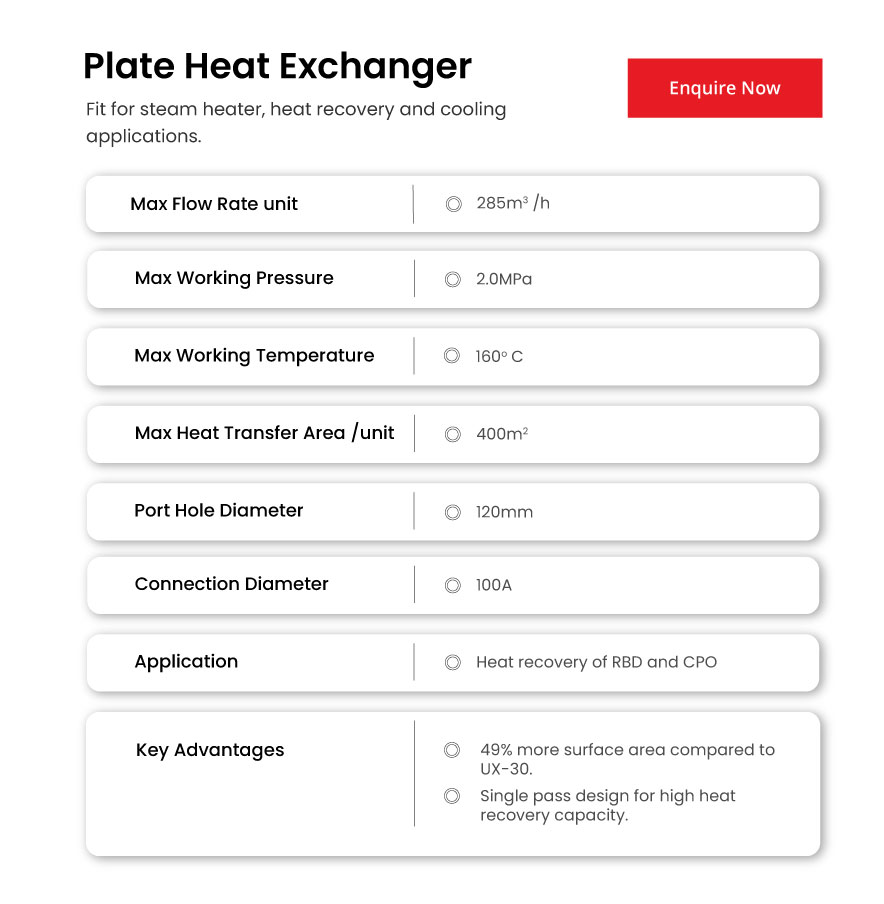

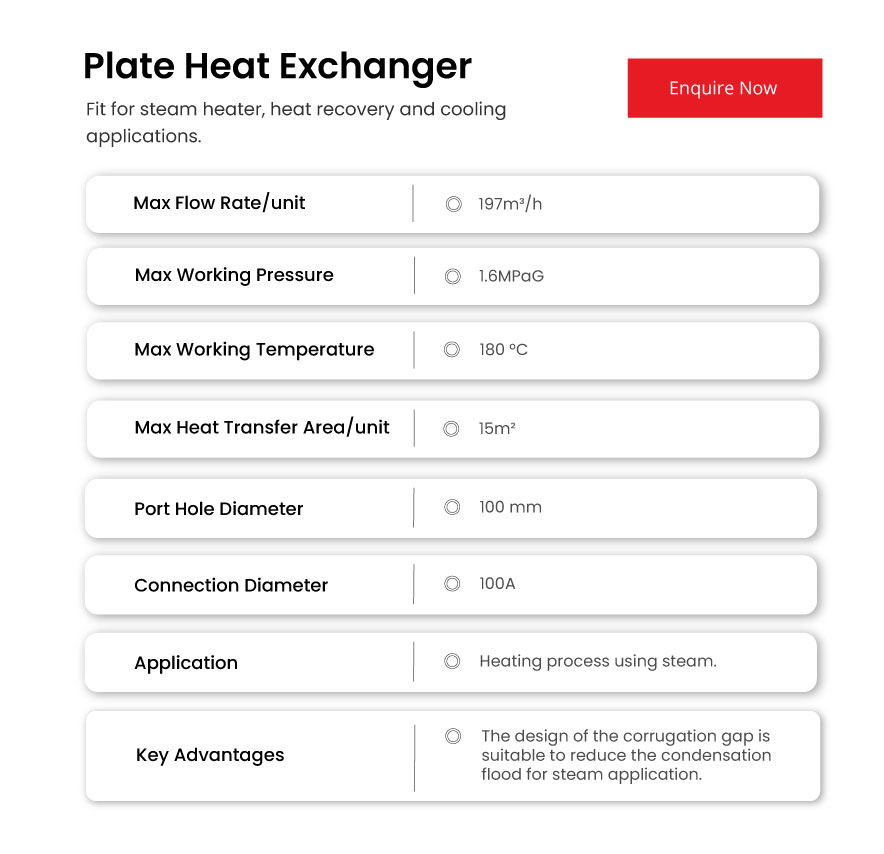

1. Deodorization stage - Gasket plate heat exchanger can be used as an economizer to control temperature of crude palm oil and RBD palm oil.

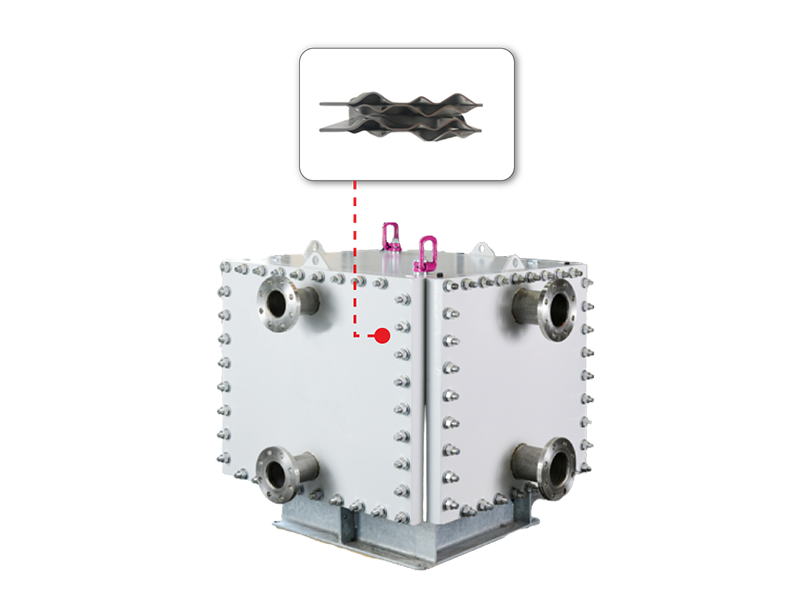

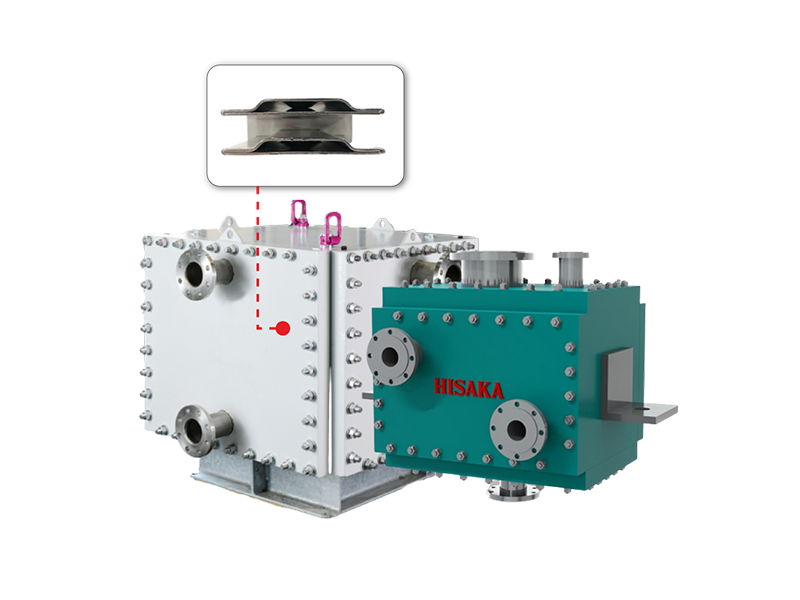

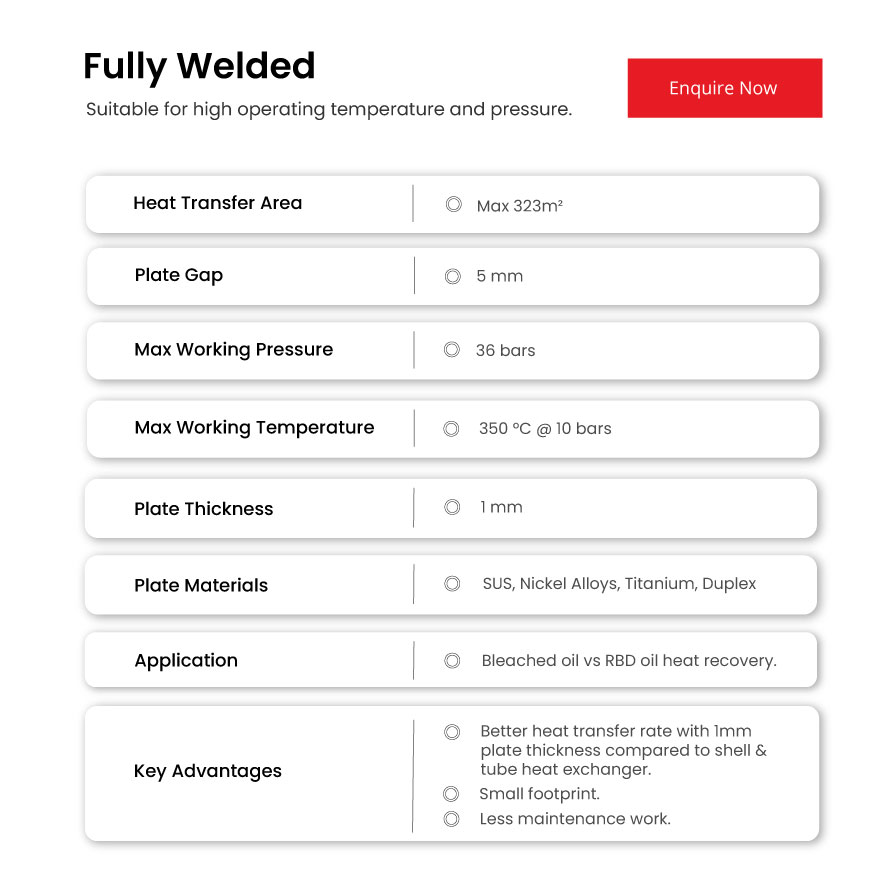

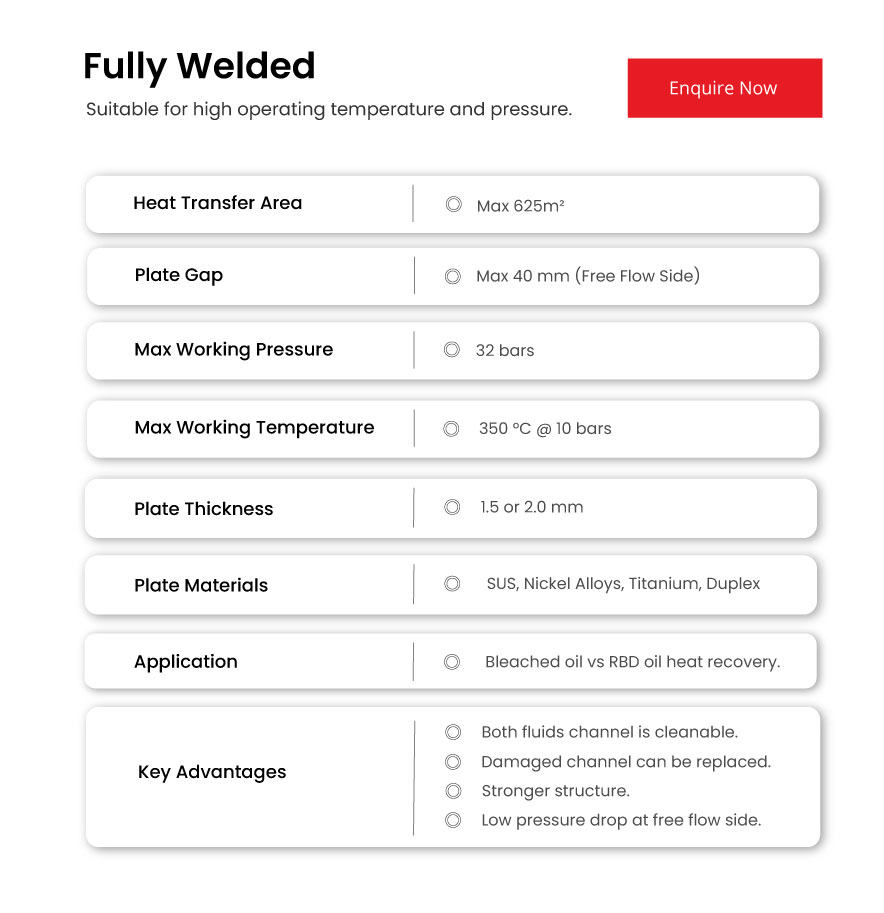

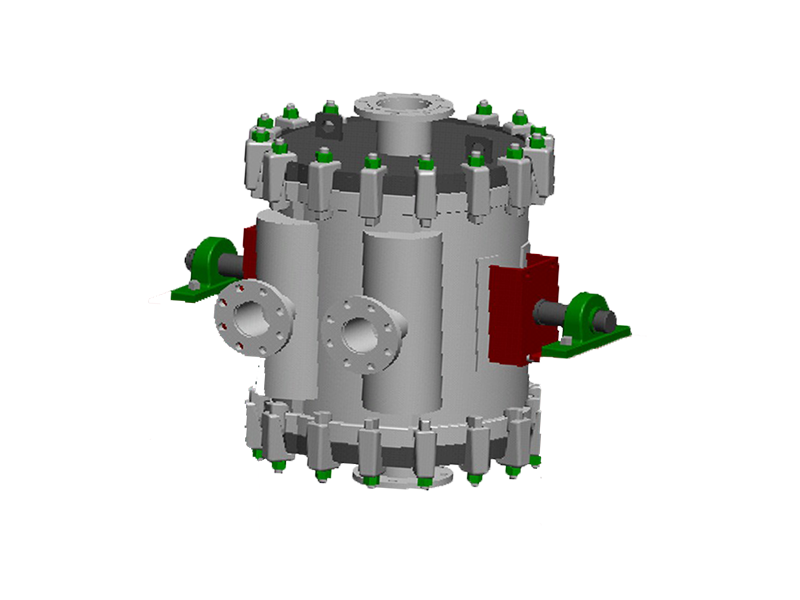

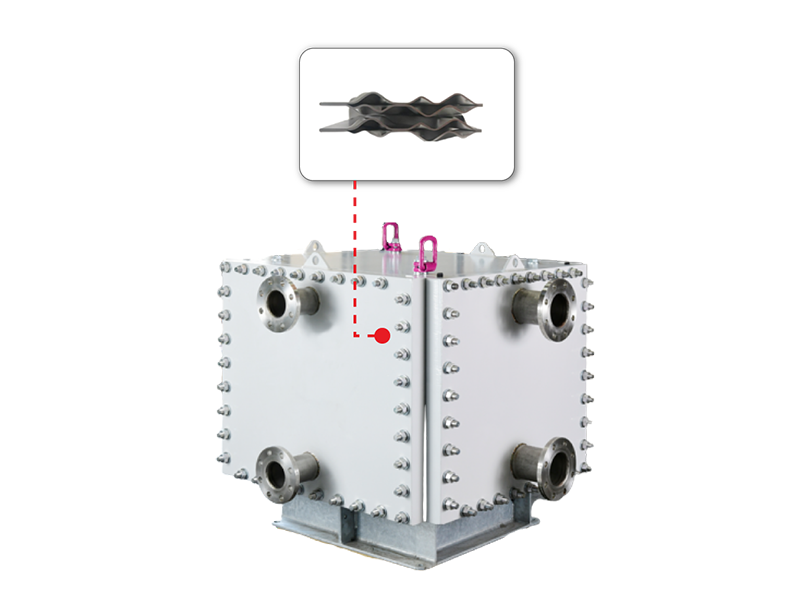

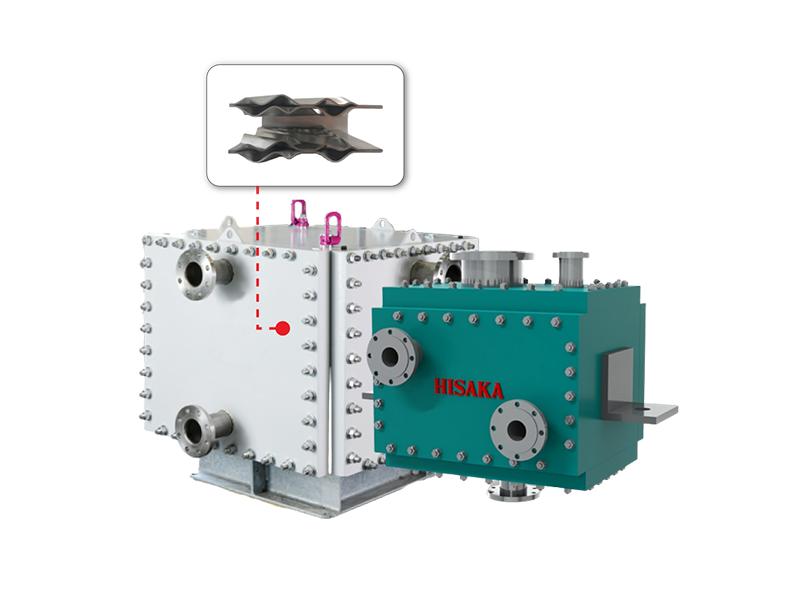

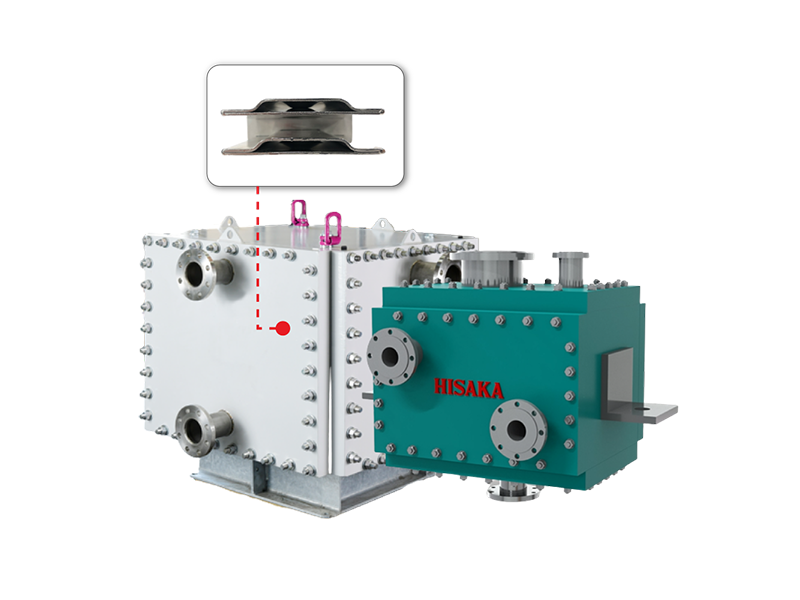

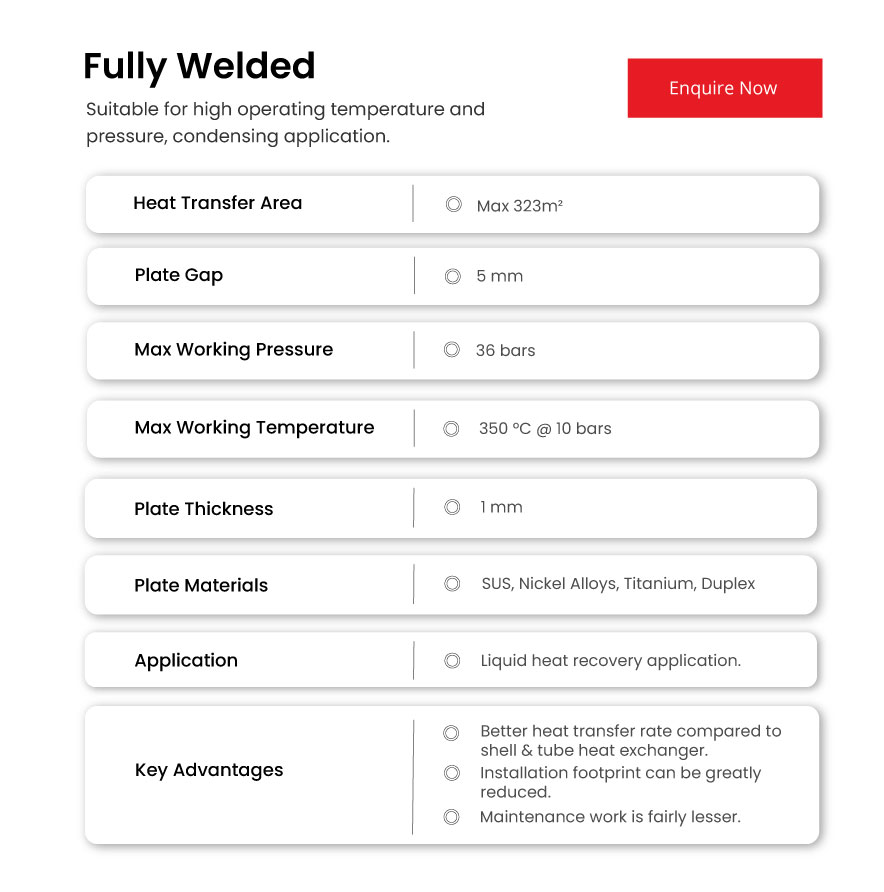

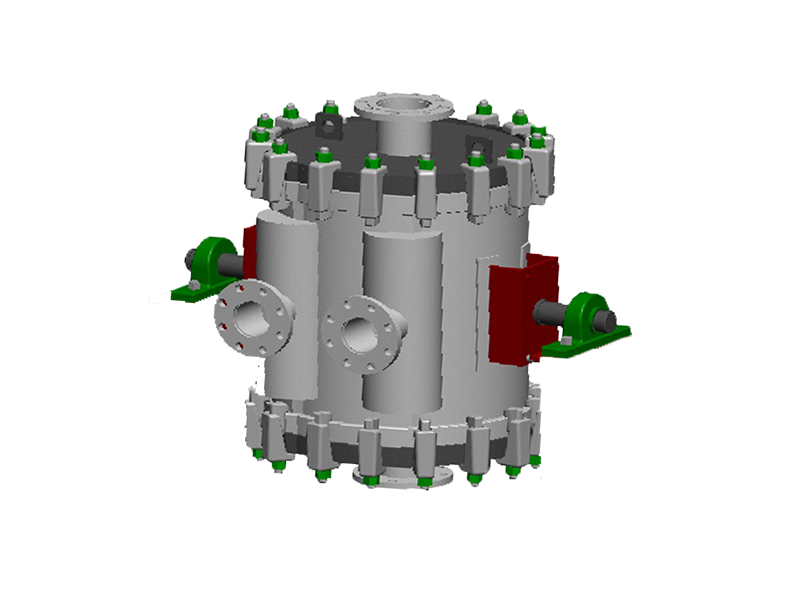

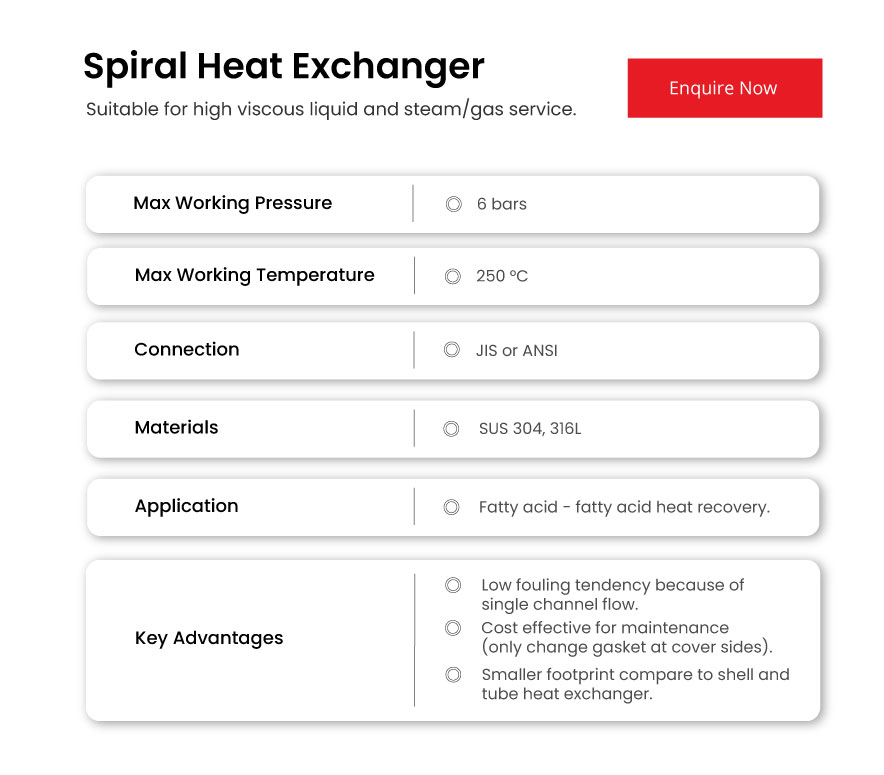

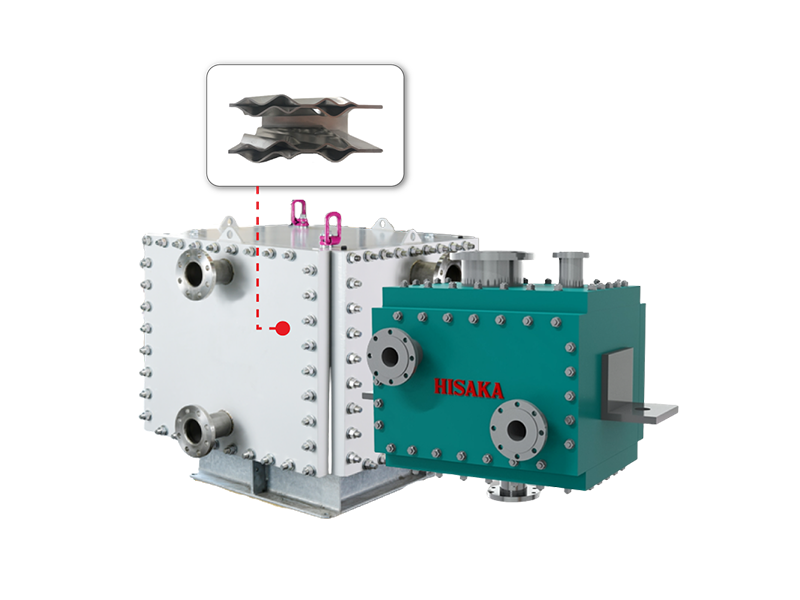

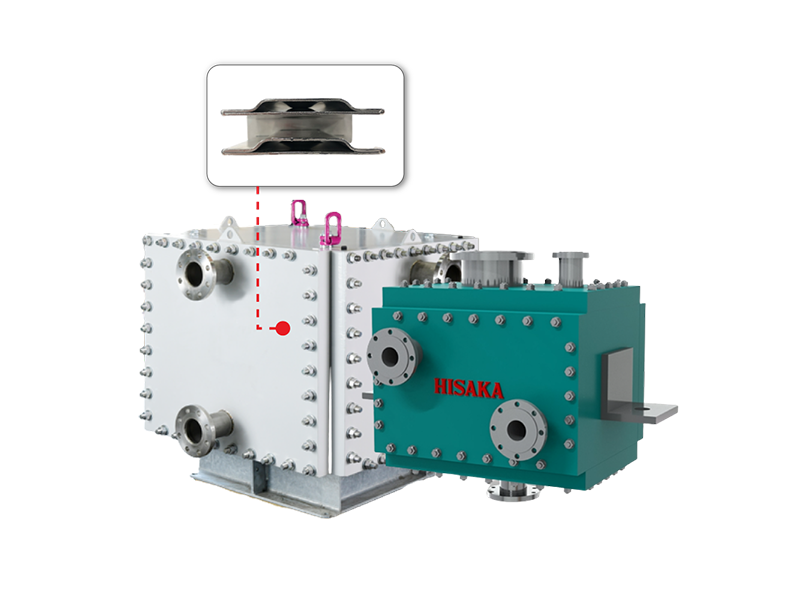

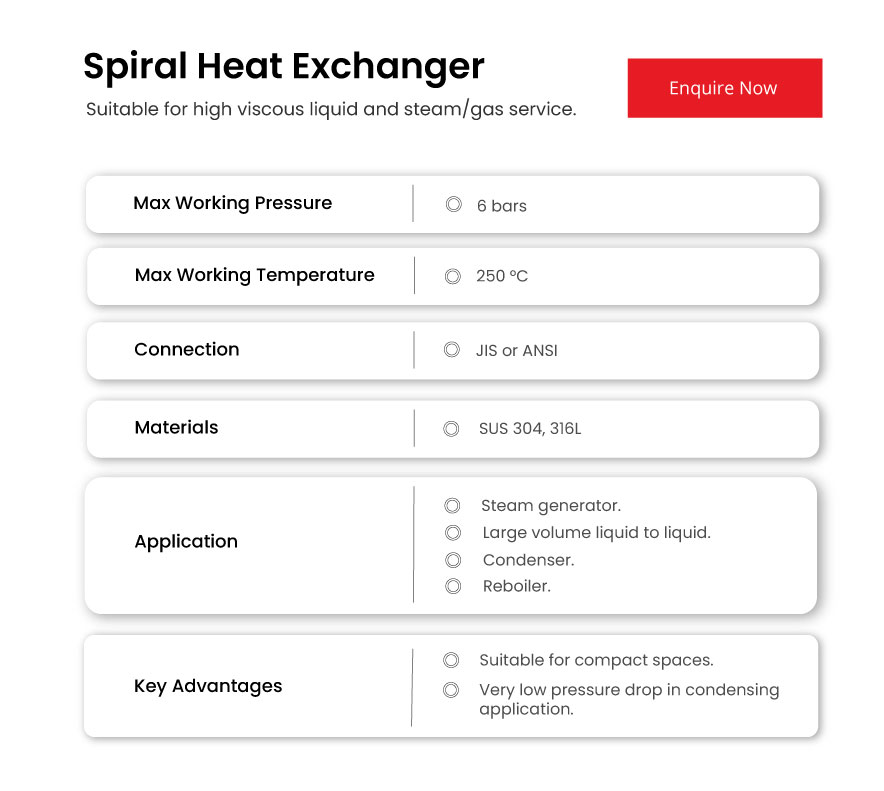

2. Deodorization stage - Fully welded or spiral heat exchanger can be used as a high temperature economizer for bleached palm oil/RBD palm oil.

We Here To Help !

Our Suggestion On Common Maintenance Issues

Issue 1: Water scaling

This issue may happen when high concentration of CaCO3 in water. The salt is easier to scale at higher temperature.

HISAKA suggestions:

- Plan proper preventive maintenance to avoid hard scaling.

- Use suitable chemicals to clean the heat exchanger plate.

Issue 2: Hard steam scaling

This issue is happened due to the impurities contained in the steam. After a long period of operation, the scale will build up because CaCO3 is highly deposited at higher temperature. This issue will reduce the heat transfer efficiency.

HISAKA suggestions:

- Proper preventive maintenance planning is required to prevent hard scaling.

- Treat the boiler feed water with sufficient chemical.

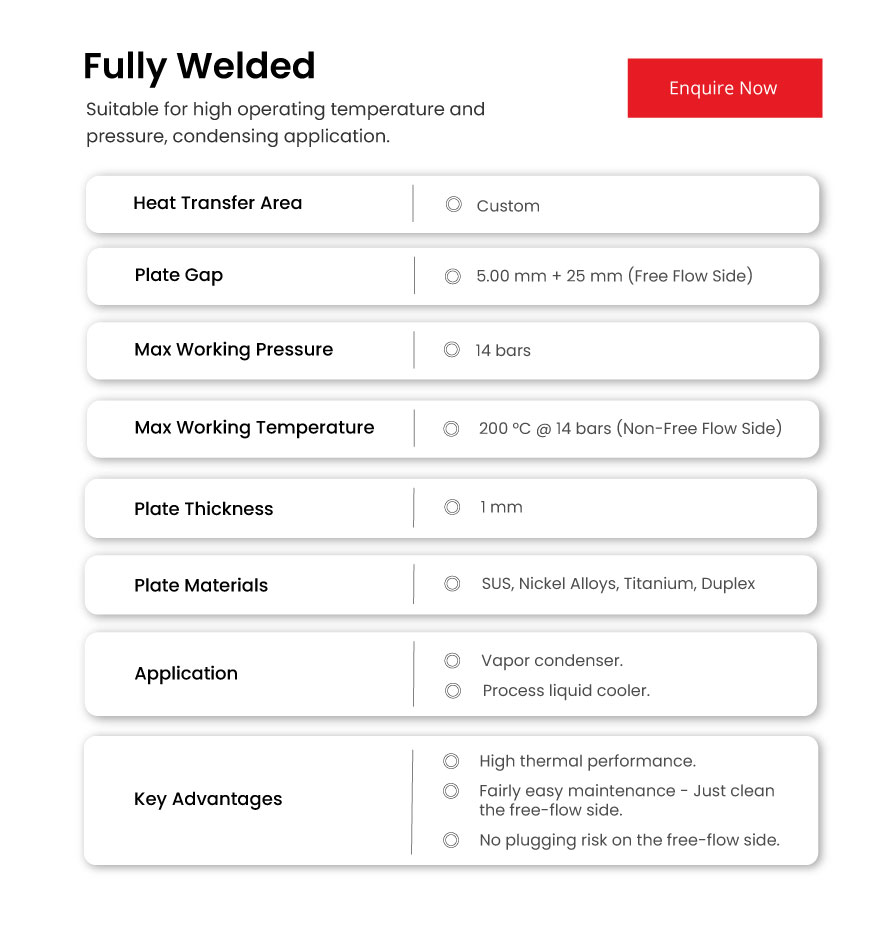

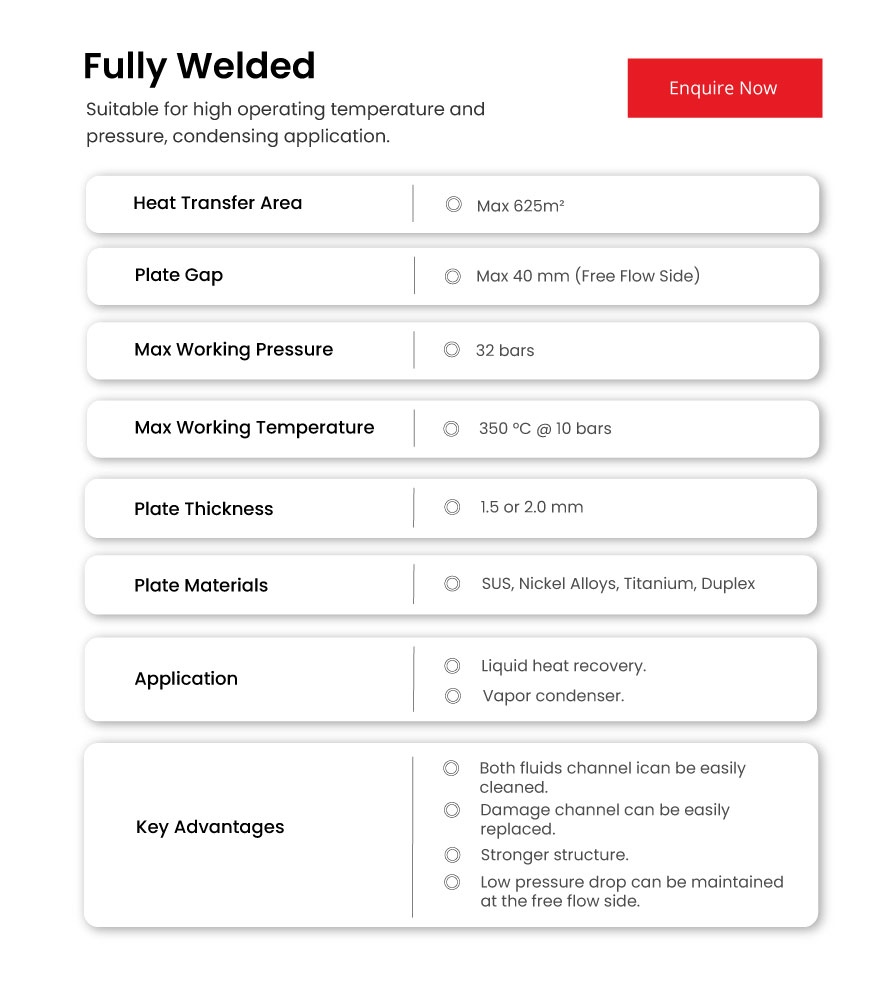

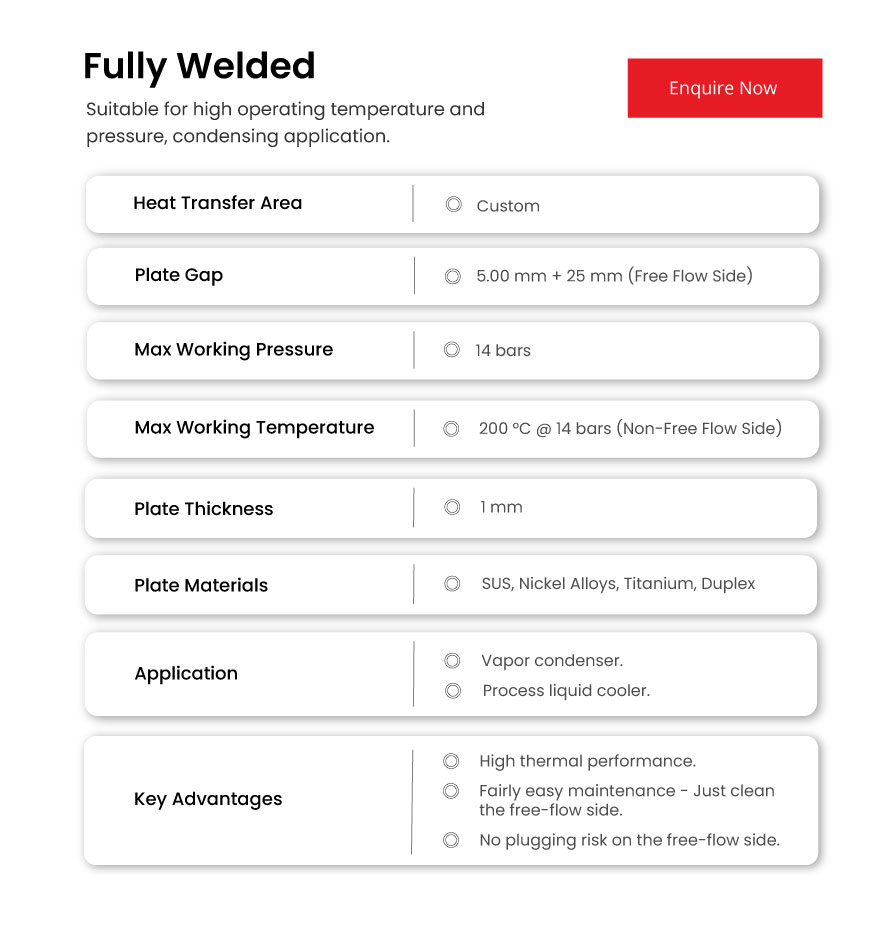

UX-30

UX-30 UX-30L

UX-30L WX-10

WX-10

HXC

HXC HXE

HXE

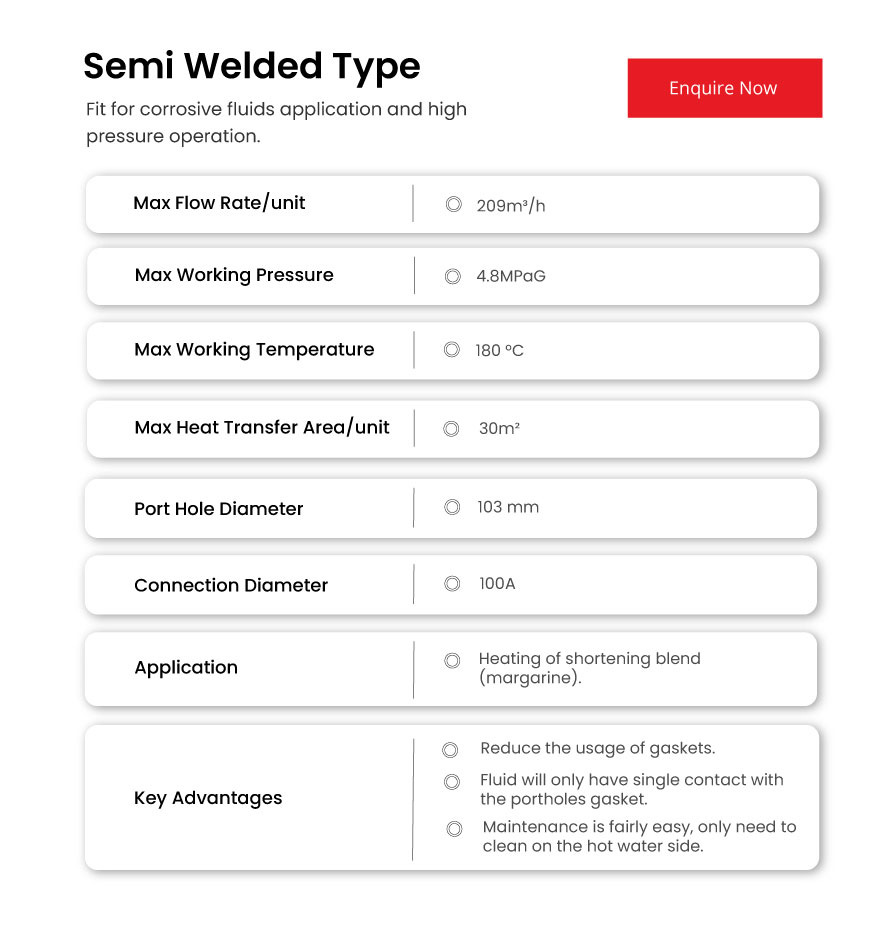

KSH-1V

KSH-1V

HF5-ST

HF5-ST TF5

TF5

LX-10

LX-10 RX-10

RX-10

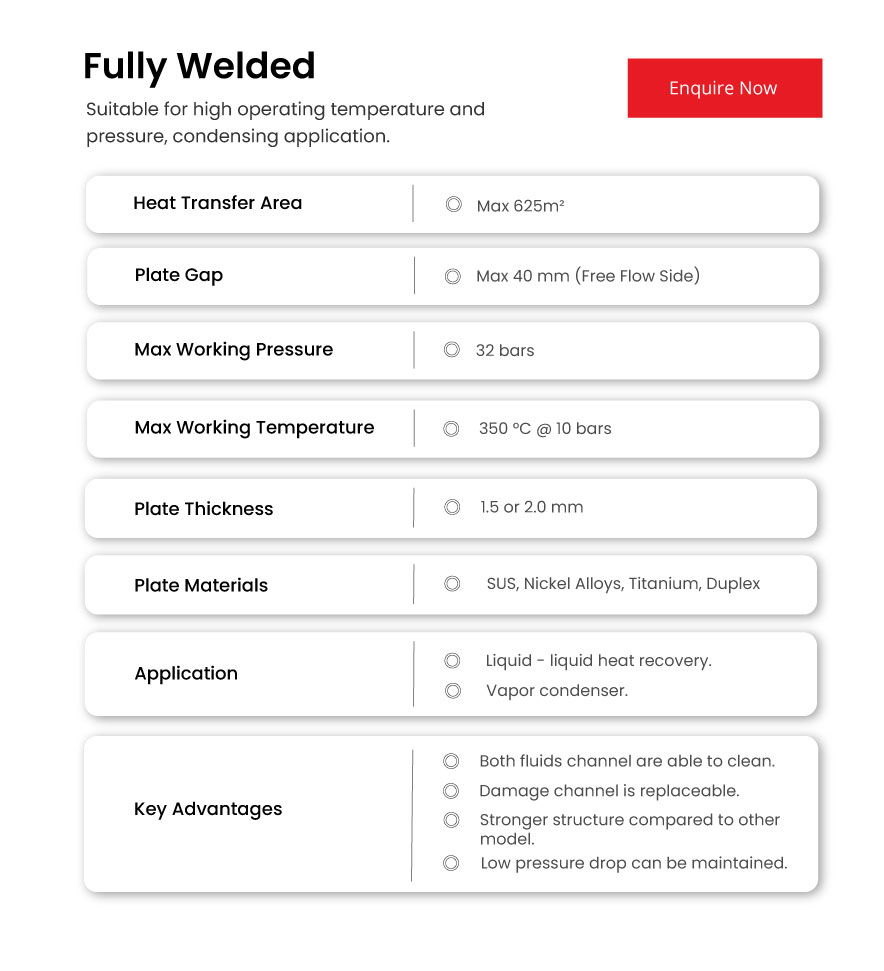

WX-10

WX-10 YX-80

YX-80

HXC

HXC HXC-FF

HXC-FF HXE

HXE

KSH-1V

KSH-1V KSH-2V

KSH-2V

HJ5

HJ5 HF5-M1

HF5-M1 HF5-ST

HF5-ST

RX-10

RX-10

WX-10

WX-10

HXC-FF

HXC-FF HXE

HXE

KSH-2V

KSH-2V

HF5-ST

HF5-ST HF5-M1

HF5-M1