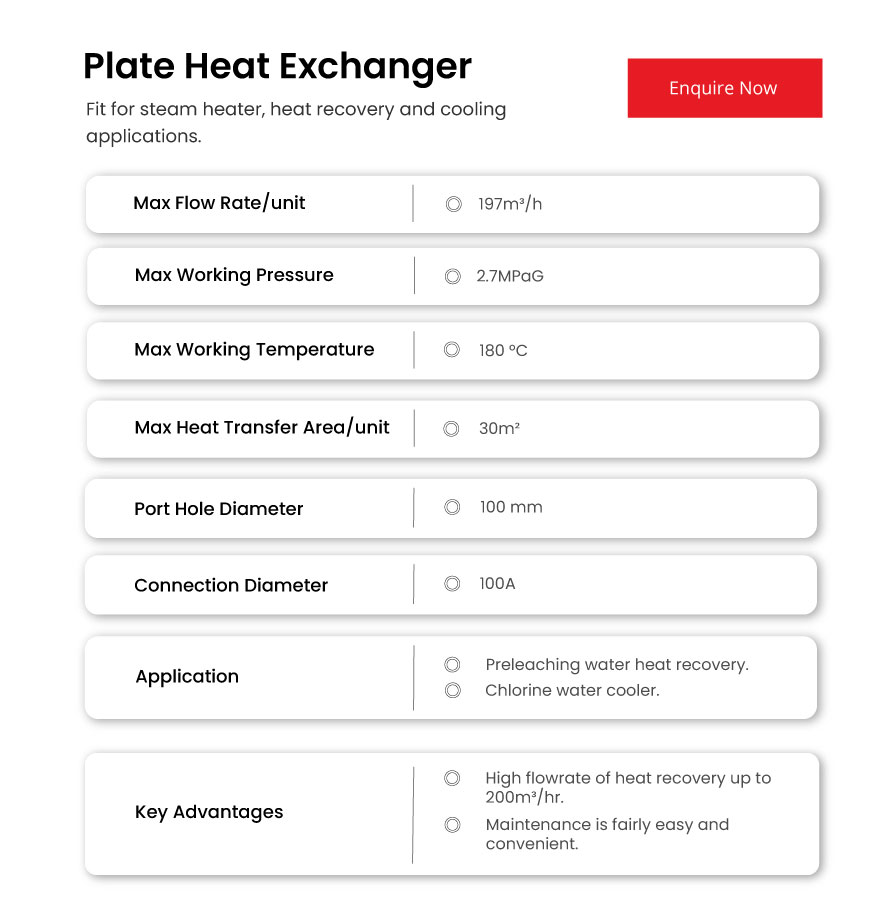

We Here To Help !

Our Suggestion On Common Maintenance Issues

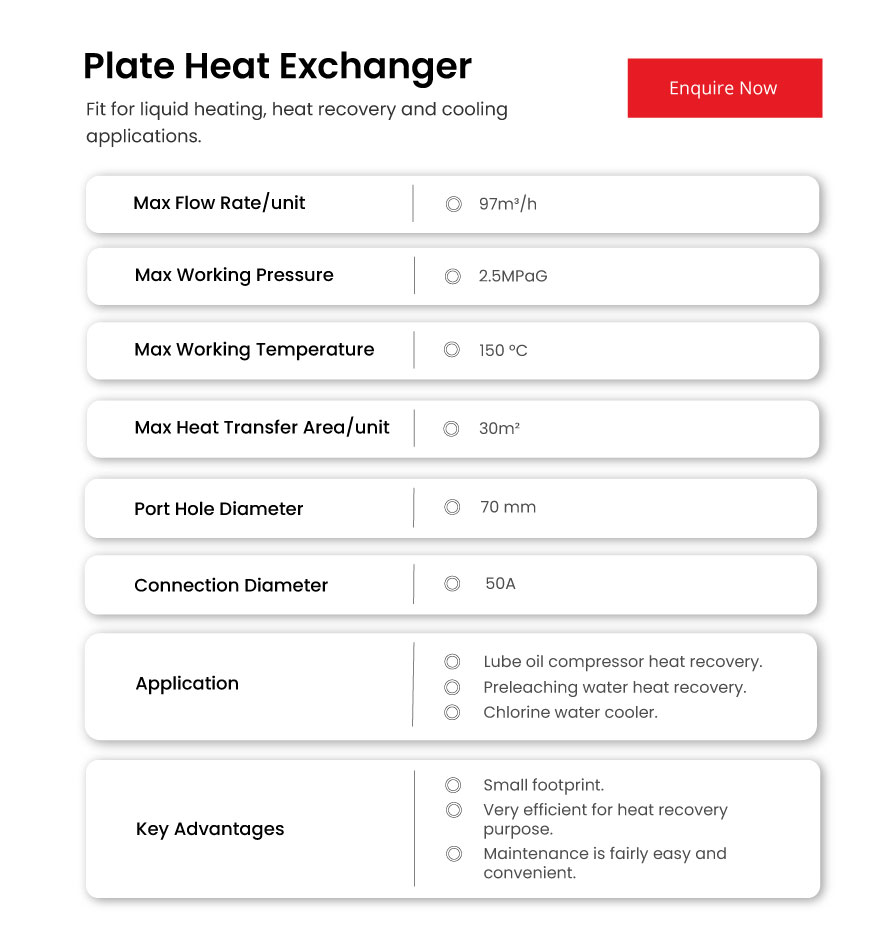

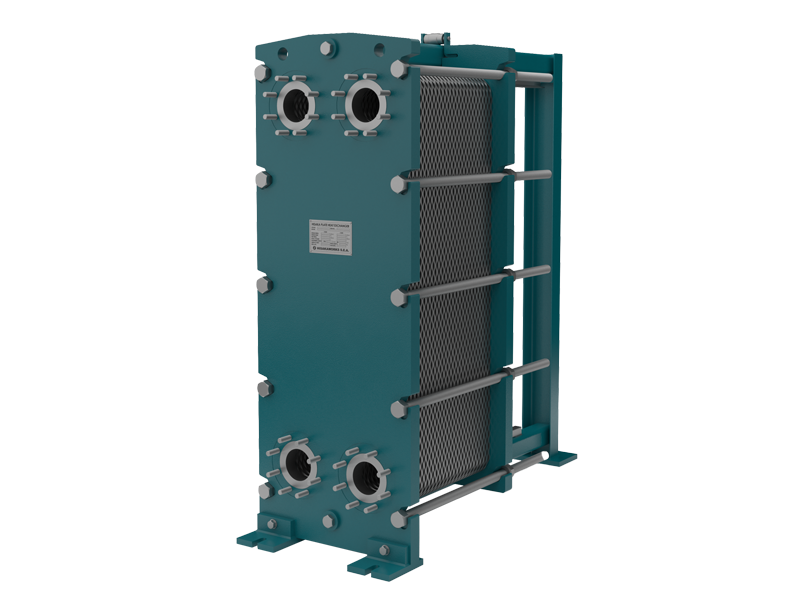

Issue 1: Leaking from compressor oil heat recovery unit

This issue may occur if the unit is running for a long period of time which exceed the operating temperature. The gasket became harden and thinner that caused leakage to occur.

HISAKA suggestions:

- Maintain operating temperature within design specification.

- Select a higher grade of gasket material.

- Plan proper preventive maintenance.

.jpg)

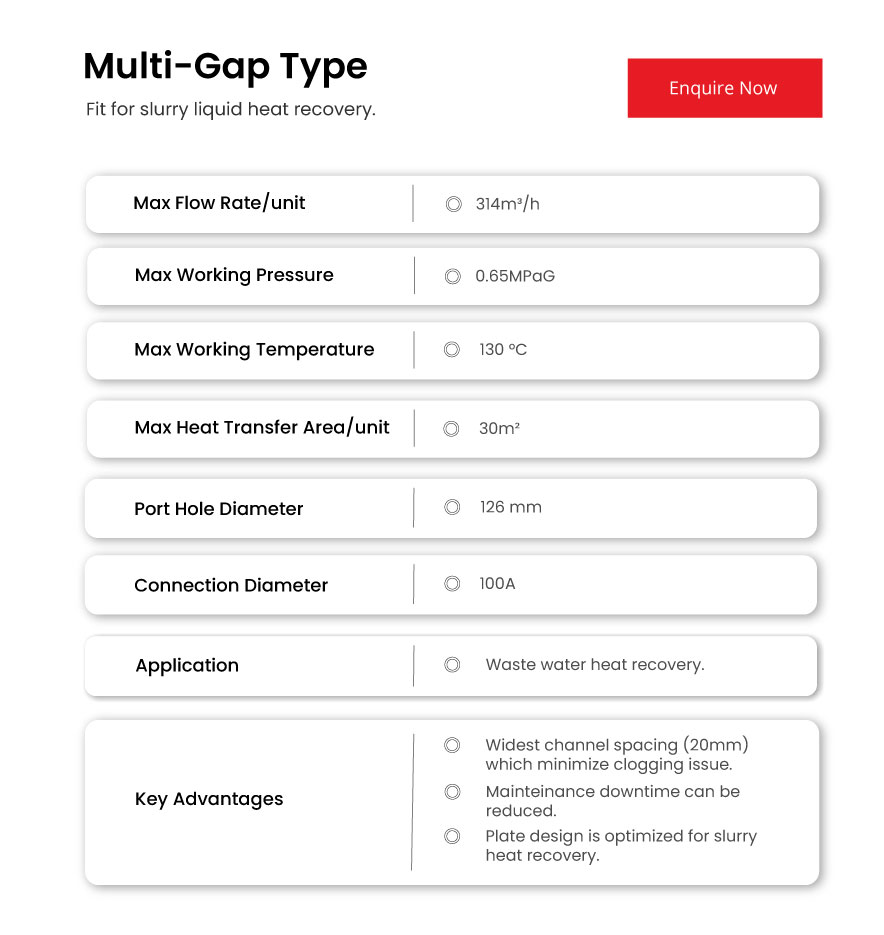

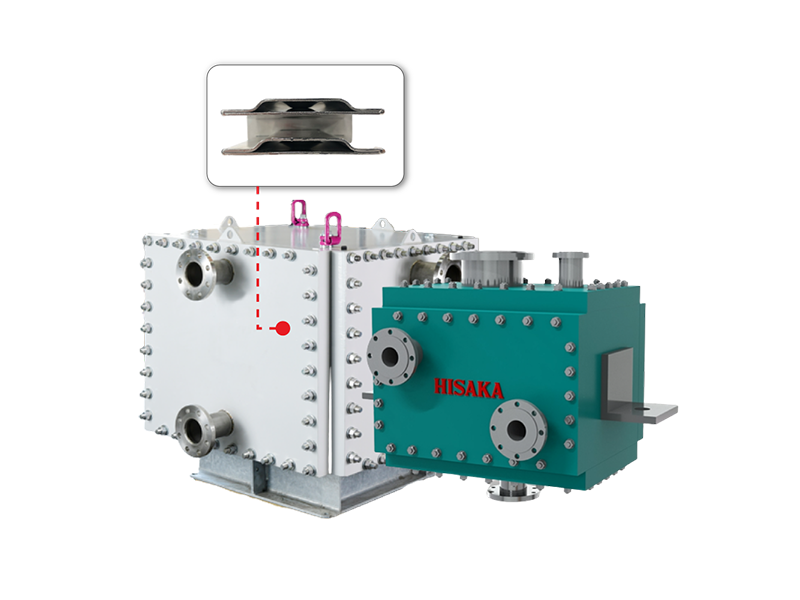

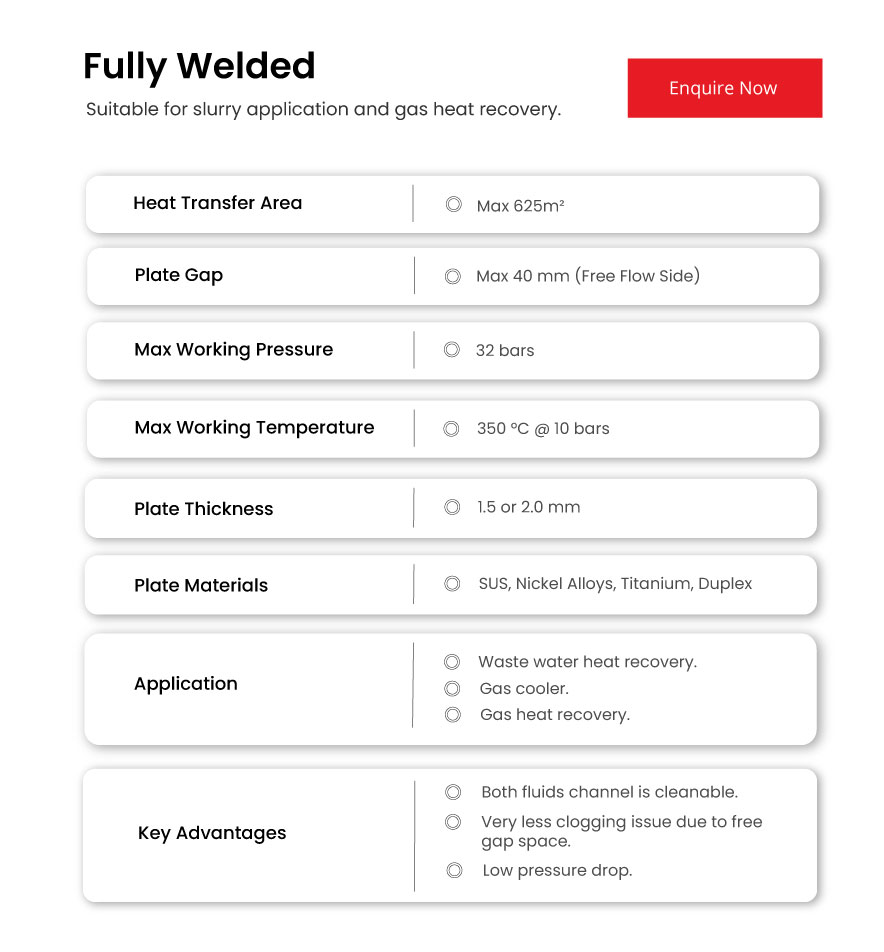

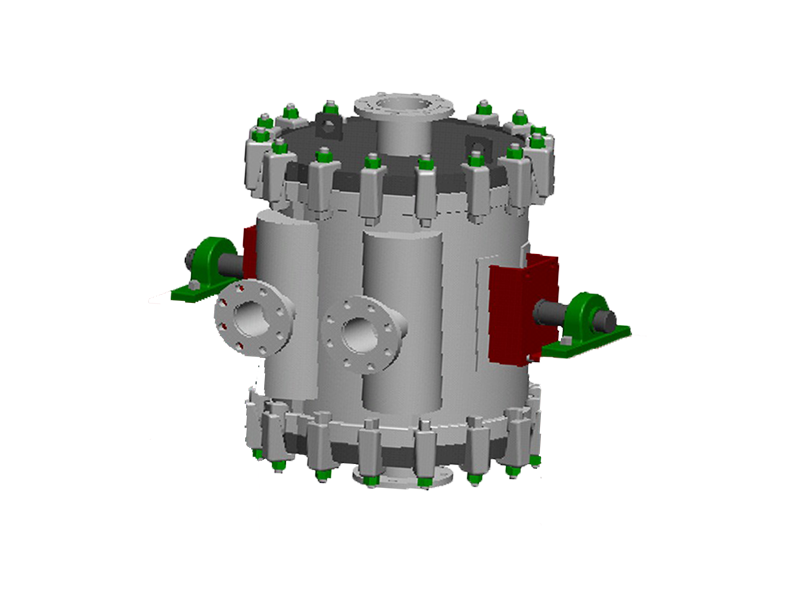

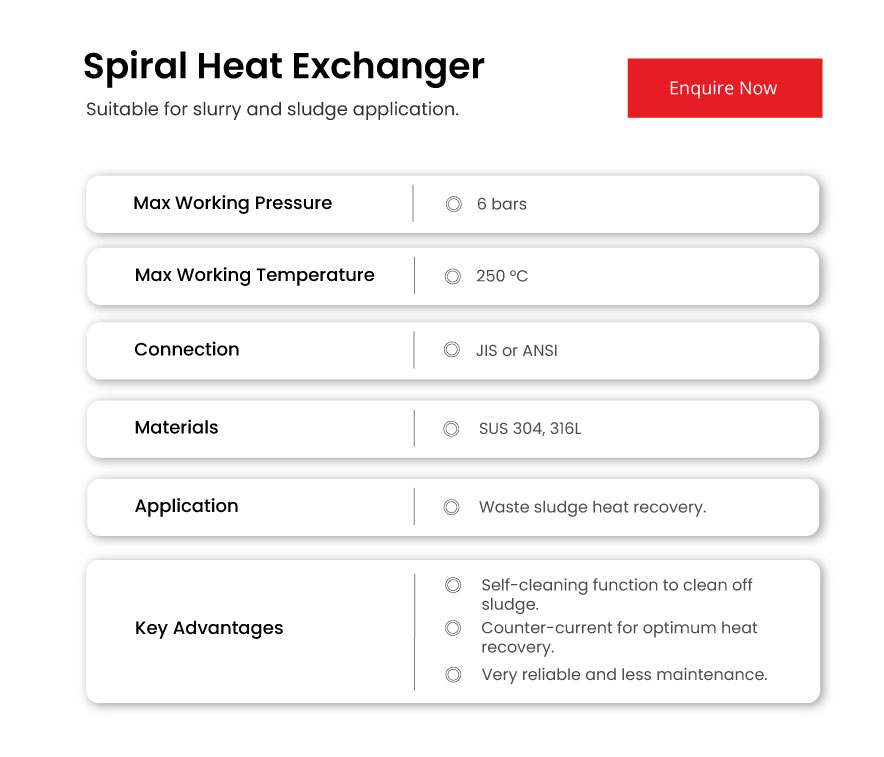

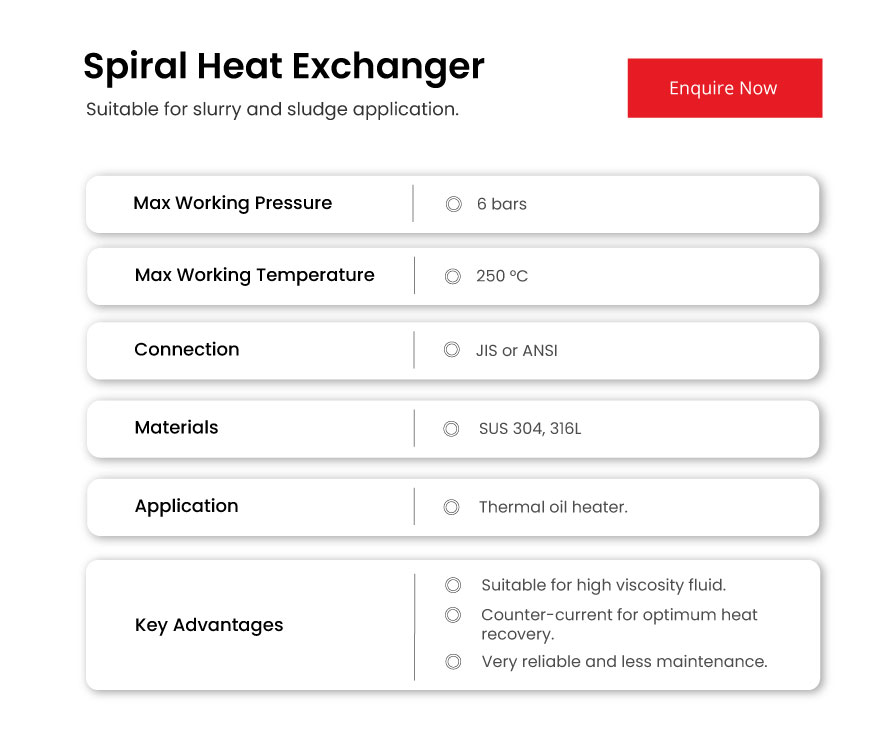

Issue 2: Waste water mud

This issue happens because of liquid flow is too dirty and contains a lot of waste. Not suitable plate gap will cause this fouling to happen very quickly which end up decrease the heat transfer efficiency of the heat exchanger.

HISAKA suggestions:

- Change to multi-gap plate pattern.

- Change to fully welded or spiral type heat exchanger.

- Add a number of plates or stand-by units.

RX-10

RX-10 UX-10

UX-10

GX-20

GX-20

HXE

HXE

KSH-1H

KSH-1H KSH-1V

KSH-1V

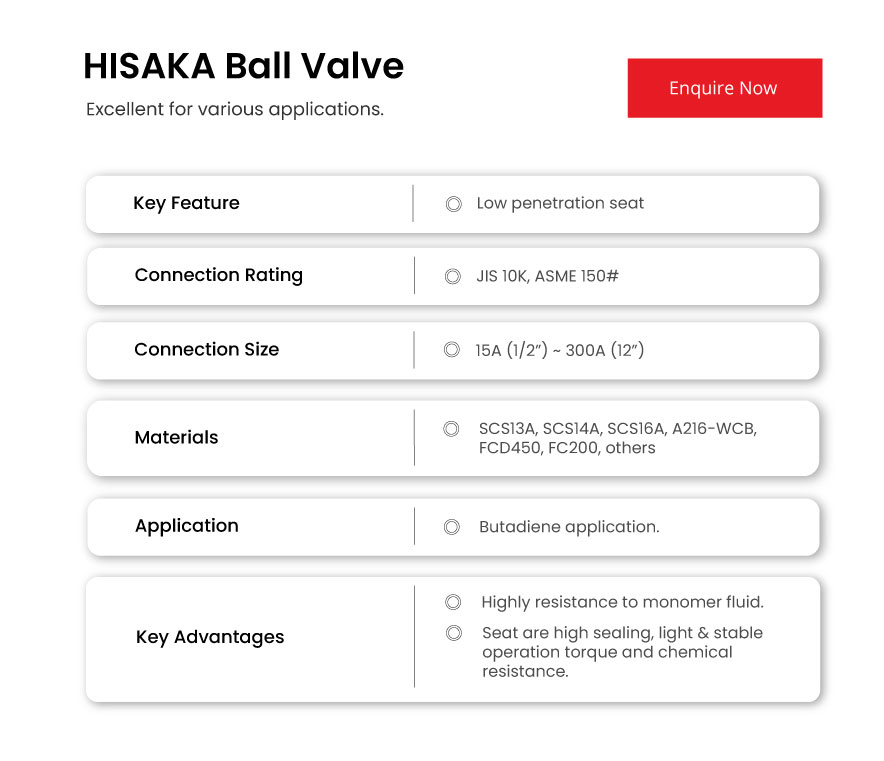

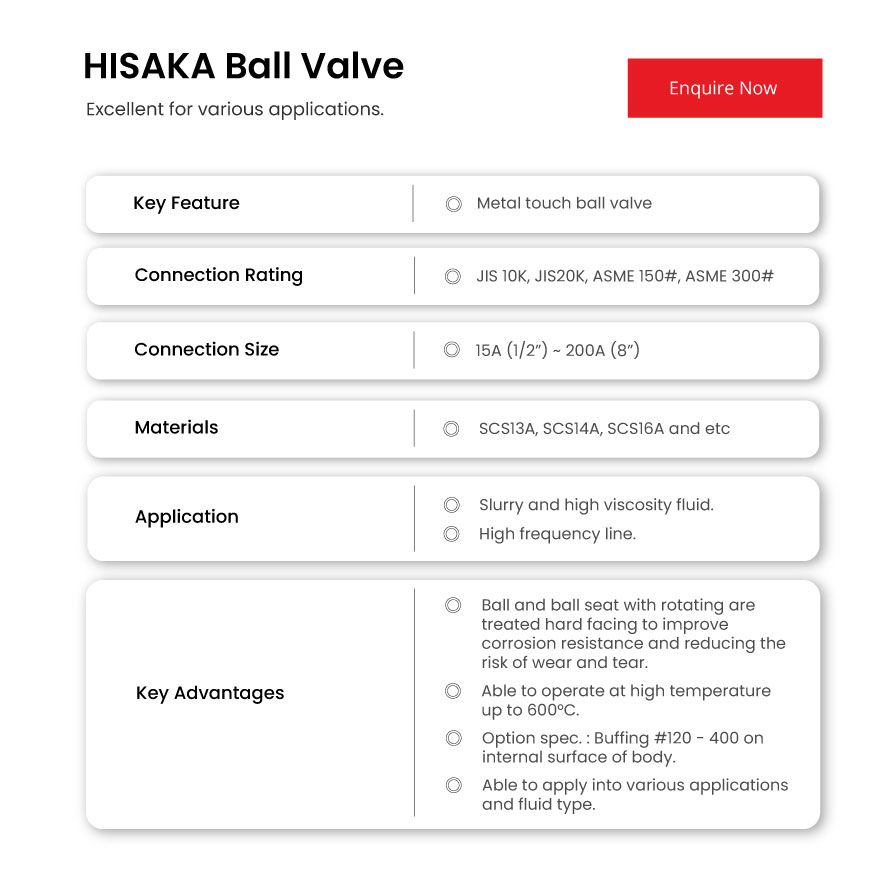

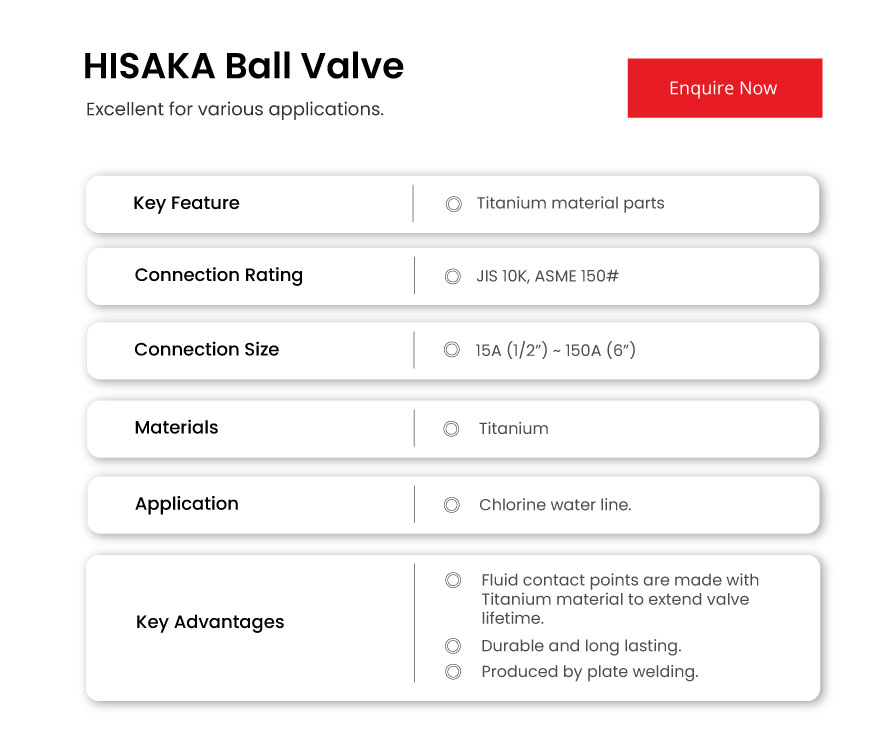

HF5-LP

HF5-LP HF5-M1

HF5-M1 HF5-TI

HF5-TI