Spiral heat exchangers are engineered and designed to be reliable and durable which can handle various heat transfer requirements. With its self-cleaning feature, it can efficiently handle slurry, viscous fluid even dirty media. More so, with its robust and efficient design, spiral plate heat exchanger can be used for cooling, heating, or even heat recovery.

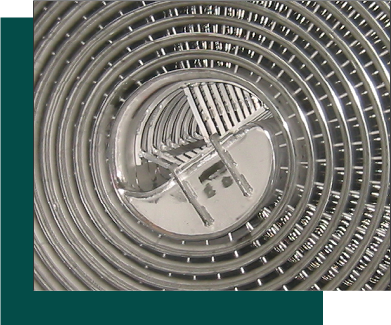

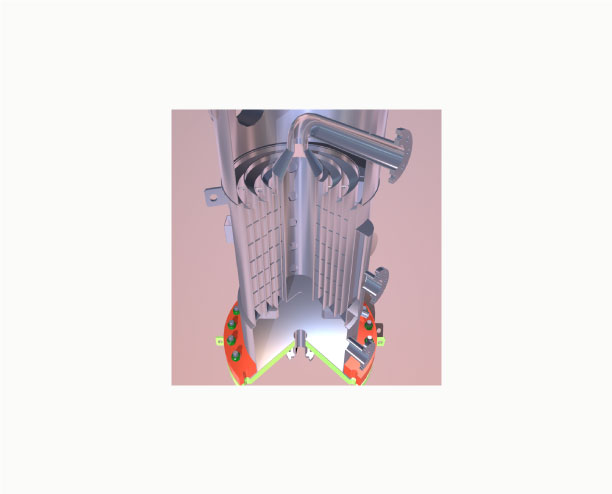

Spiral Heat Exchanger consists of two long flat plates wrapped around a center, creating two concentric spiral channels. The hot and cold fluid channel into the spiral heat exchanger counter-current to maximize heat transfer. The velocity of the fluid increases when there's a deposit in the spiral heat exchanger which will cause scrubbing effect that removes the deposits.

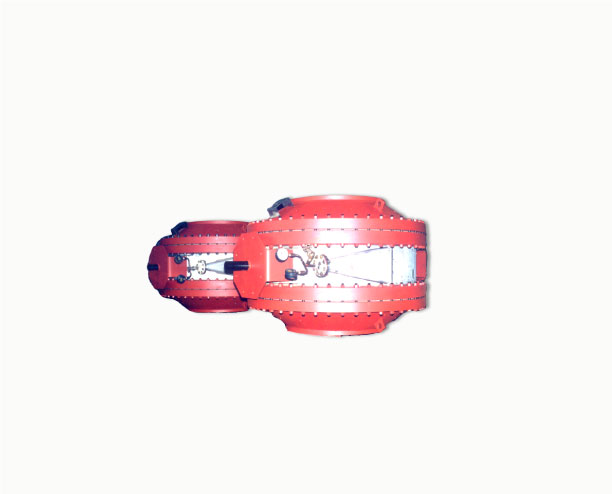

SLURRY heat exchanger designed to minimize the accumulation of slurry. With this, fluid can flow smoothly inside the heat exchanger without accumulation of fouling. Our slurry heat exchanger is the only licensed product for CHISSO process.

Our KSH-1HK model is designed specifically for fiber or sludge-contained fluid. With no stud in between the spiral gap, the slurry can flow smoothly across the spiral heat exchanger. As a typical spiral heat exchanger, a distance piece or stud is present between the spiral gap which friction between the slurry liquid and the stud increases. This will increase the fouling rate in the long run.

Our KSH-2V model is specially designed for high viscous liquid. With minimum tolerance along the channel, uniform gap will be created for the liquid to flow uniformly along the spiral channel without leaving any non-active area.

Eager to know more about HISAKA spiral heat exchanger? Fill up the form below and our dedicated specialist will contact you as soon as possible. Or do you have specific requirements for your spiral heat exchanger? Provide us the specification you need and our specialist can suggest the most suitable model for you. If urgent, you can always contact our nearest agents or sales representative.