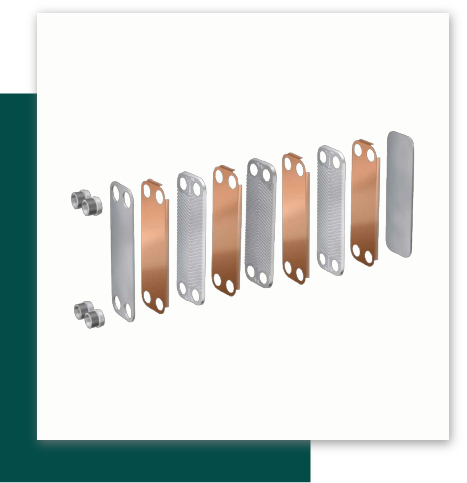

High performance, small footprint, light, and durability make HISAKA brazed plate heat exchangers suitable for limited space applications. Even with a simpler structure, HISAKA BHE has its own unique features to apply to various applications ensuring efficient thermal performance and reliability.

The fluid flow and movement is similar to plate heat exchanger (PHE). However, fluid inside BHE would not have contact with any gasket sealing material. Therefore, lower or higher fluid temperature can be operate inside the BHE. The hot fluid and cold fluid flow in alternate directions through the heat transfer plates.

Our BMC-007 brazed heat exchangers are commonly used in reheating bathwater, due to their higher heat transfer coefficient than conventional tube heat exchangers.

Our BXC-084 is designed to efficiently heat the water to set temperature. BXC-084 uses quick nozzles as standard to allow smooth design on hot water heaters.

Our BXC-016D is designed enhancing on the safety element. With double-wall plate structures, intermixing between two fluids can be prevented

Our BXP series brazed heat exchanger is designed using nickel brazing filler metal to enhance its durability. With nickel brazing filler, its anti-corrosive properties are also further enhanced, which made our BXP series can be applied on various applications.

Eager to know more about HISAKA brazed heat exchanger? Fill up the form below and our dedicated specialist will contact you as soon as possible. Or do you have specific requirements for your BHE? Provide us the specification you need and our specialist can suggest the most suitable model for you. If urgent, you can always contact our nearest agents or sales representative.