District Cooling system is a cooling system where Chilled Water is produced by a plant and supplied to tenant buildings through insulate pipes. This engineering marvel is only done by a well-considered urbanization plan. In comparison with previous decades, each building uses their own chiller for their cooling respectively. Performance, as well as maintenance varies for each building. Whereas now district cooling is commonly applied in new developed cities, building owners just purchase chilled water from District Cooling, saving them maintenance and management costs.

.png) PHE is used in DCP intake station as well as tenant side. For tenant side, PHE is used when receiving chilled water. PHE is often used because its ability to provide indirect cooling. Installing PHE in between a chill water line is only 1C difference. Because of this, PHE can be used as pressure breaker isolating primary and secondary water which each has different pressure. Indirect cooling is also used to clearly separate Chilled water from DCP with building side chilled water.

PHE is used in DCP intake station as well as tenant side. For tenant side, PHE is used when receiving chilled water. PHE is often used because its ability to provide indirect cooling. Installing PHE in between a chill water line is only 1C difference. Because of this, PHE can be used as pressure breaker isolating primary and secondary water which each has different pressure. Indirect cooling is also used to clearly separate Chilled water from DCP with building side chilled water.

Indirect cooling has many advantages despite there is 1C drop compare to direct cooling. Among others are cost down for piping and other equipment. As high-pressure side needs thicker pipe higher pressure rating materials, isolating high pressure line from low pressure means you don’t have to have high pressure material throughout the whole building. This significantly reduce capital expenses as well as operating expenses should you need to replace the parts.

Separating different loops of water also has the advantage of simplifying maintenance problem. Should one of the loops having problem or contamination, maintenance can be targeted for that part only.

For District Cooling Plant, PHE is located at intake station. Individual PHE is there for each specific tenant ensuring temperature and flow is supplied precisely.

Having both primary and secondary chilled water within the same unit makes the whole PHE having lower than ambient temperature. Although there is minimal heat loss or gain for the plate pack, the whole PHE will have an equilibrium temperature of the average temperature between hottest and coolest fluid entering the unit.

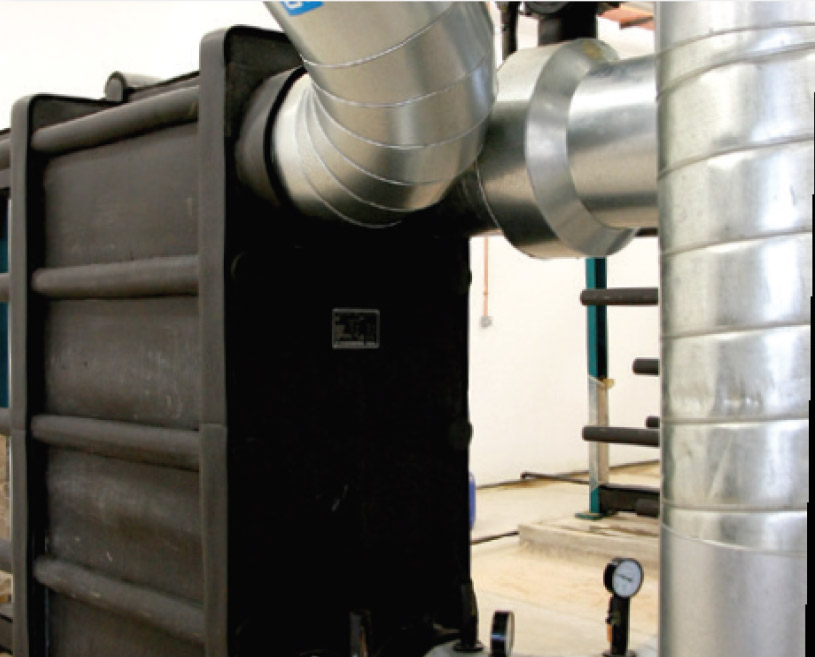

Low temperature of metal surface will attract condensation on it when humidity of the room is high. Condensation on surface may lead to corrosion if not properly managed. To tackle such issue, insulation is applied on the PHE to minimize condensation.

There are two common types of insulation. Flexible Insulation and Panel type.

Flexible insulation is directly attached to all metal surfaces.

The advantage of this method is that all surface are covered, which avoid any surface having condensation.

The disadvantage is that when maintenance is needed, flexible insulation needs to be peeled off and install anew.

Cost wise, it is lower than Panel type.

Panel type insulation on the other hand is detachable and reusable. The panel covers most of the PHE surface. Even there is gap between panel and metal surfaces, the gap is minimal and it is not humid to have significant condensation. During maintenance of PHE, panels can be detached and can be assembled again after maintenance complete.

Cost wise it is more expensive than flexible insulation. Established owner and contractors often opt for this choice.

Plate pack as we call it is the bundle of plates and gasket in between frames. It is the core of the heat exchanger where heat exchanger takes place. The surface of the plates may have fouling from time to time if the water quality and temperature is not controlled well. Fouling on the surface reduces heat transfer ability. In worse case, it develops into scaling and corrosion on the plate surface. Regular maintenance is required to ensure performance and longevity of the unit.

The plates are often Stainless steel with 0.4 and 0.5mm thickness thin for heat transfer purpose. It is important to select proper surface area to avoid performance issues.

Global warming is constantly a serious problem in our modern world. The results of the pace of industrialization require a need of more green ideas. At Hisaka, plate heat exchangers are regarded as a key technology that powerfully supports the society to generate optimum productivity of results such as DCP, cogeneration systems, and heat pump systems. Hisaka offers higher efficiency and higher energy conservation while diligently constantly developing better plate technologies. HISAKA continues to labor for a higher improvement not only to our products but through the entire organization, we ensure continuous innovation and originality for Plate Heat Exchangers.