Semi welded plate heat exchanger works exactly the same as typical gasket plate heat exchanger. The main difference is, a couple of plates are laser welded with O-ring at portholes between the plates. One fluid flowing through the inside of the cassettes and the other fluid flowing on the outside of the cassettes.

.png)

High heat transfer coefficient created from uniform distribution of flow to entire heat transfer is by special plate pattern. A couple of plates are laser welded with an O-ring at portholes between the plates, thus semi-welded plate heat exchanger can be used for higher pressure compared to a conventional Plate Heat Exchanger.

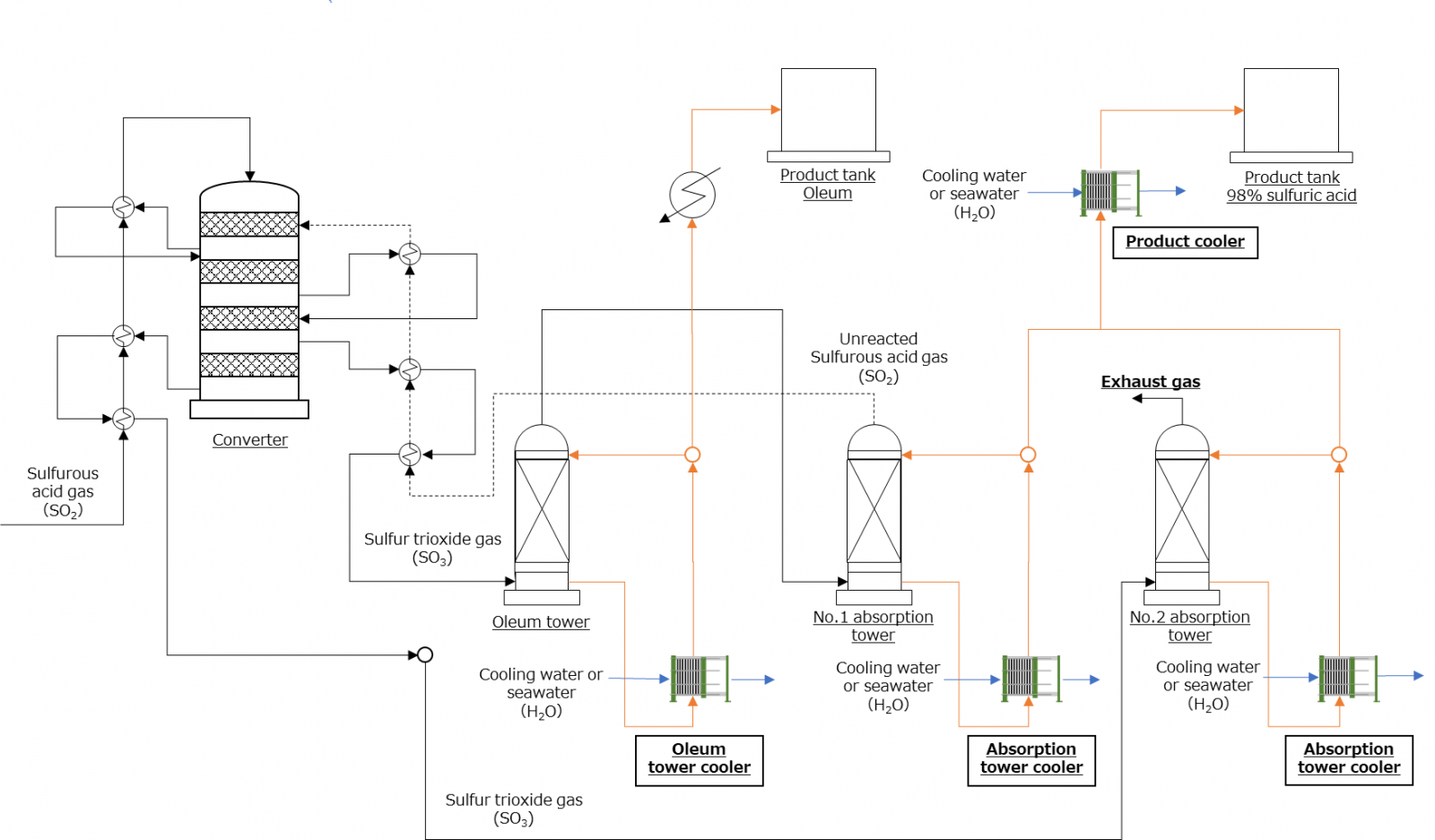

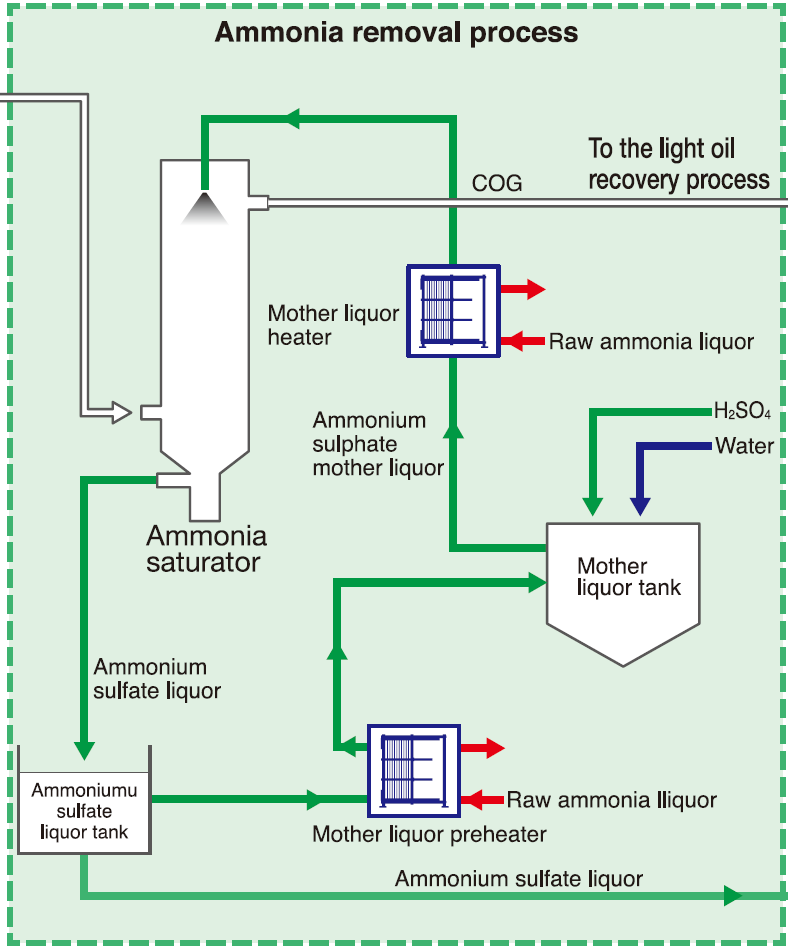

Semi welded plate heat exchangers are commonly used in Sulfuric Acid, BTX Recovering processes, and many other industrial processes. HISAKA WX series is made to perform in rough conditions due to a special welded design.

If your plate heat exchanger frequently leaked due to the gasket, this may be initiated from gasket incompatibility and degraded of sealing performance. With laser welded technology, the sealing ability is more secure and sturdy against corrosive fluid!